A health and safety policy is your company's documented plan for managing risks and keeping people safe. It’s not just more paperwork. Think of it as a practical guide that clearly defines who is responsible for what and outlines the specific steps your team must follow to prevent incidents on site.

Why Your Business Needs a Solid Safety Policy

Treating your health and safety policy as just another folder gathering dust is a costly mistake. For high-risk industries like construction and manufacturing, a clear policy is a core business tool that directly protects your bottom line. It’s the tool that prevents serious incidents, keeps projects running on time, and makes your company a place where skilled workers want to work.

Without clear, enforced rules, you're leaving your business open to major financial and operational risks. The problems go way beyond the direct costs of an injury.

Avoid Serious Fines and Project Delays

Regulators don’t mess around when it comes to safety breaches. Failing to provide a safe work environment can lead to massive fines that can easily hurt a small or medium-sized business.

Picture this: an unguarded machine on your factory floor leads to a serious injury. The initial penalty is just the beginning. The investigation that follows could shut down production for days or even weeks. Suddenly, you’re missing critical deadlines and trying to manage damaged client relationships.

A strong policy isn't about avoiding blame after the fact; it's about preventing the incident from ever happening. It provides clear, actionable steps that, when followed, systematically reduce the chances of something going wrong.

Retain Your Best Workers

Good people have options. Skilled tradespeople and experienced operators can spot an unsafe site from a mile away, and they won't stick around if they feel their wellbeing is an afterthought. High staff turnover is a killer. It means more recruitment costs, more time spent training new hires, and a constant drain on productivity and hard-earned knowledge.

A clear, consistently enforced safety policy is a powerful signal that you value your team. It’s a massive factor in employee retention. You can dive deeper into the importance of health and safety in our detailed guide.

This commitment is part of a bigger national picture. While Australia has made solid progress, the workplace fatality rate is now 24% lower than it was a decade ago. The numbers are a stark reminder that we can't get complacent, especially in high-risk sectors. When you implement strong health and safety policies, you’re not just protecting your own business; you're contributing to this positive trend.

Building a Health and Safety Policy Document

Let's move from theory to practical steps: building the actual health and safety policy document that will guide your business.

This isn't about drafting a dense legal text that gathers dust on a shelf. The goal is to create a clear, usable guide that defines how safety actually works in your business day-to-day. It needs to be direct, easy for everyone to understand, and specific to the real-world tasks your team performs.

A solid policy document rests on a few key parts. Think of it as outlining your commitment, defining who's responsible for what, and detailing the actual processes you'll use to keep people safe.

The Policy Statement: Your Commitment

This is your opening statement, and it needs to be direct. It's a short, clear statement from senior management that spells out the company's commitment to a safe and healthy workplace. It sets the tone for everything that follows.

This statement should confirm that you'll comply with all relevant WHS legislation and standards. It's also where you state your main goals, like preventing injuries and work-related illness, and show your dedication to improving over time.

For a construction company, this might explicitly mention a commitment to managing high-risk work like operating at heights. If you're in a manufacturing plant, it could highlight a focus on safe machinery operation and handling chemicals.

Defining Roles and Responsibilities

This is where your policy gets personal and actionable. When it comes to safety, vague instructions are the enemy; everyone needs to know exactly what’s expected of them. You need to break down responsibilities for every role in the company.

- Directors and Senior Management: They’re responsible for providing resources (time, money, equipment), making sure the policy is actually used, and leading by example.

- Supervisors and Foremen: Their job is to enforce the policy on the ground. This means running daily safety checks like toolbox talks, correcting unsafe actions, and making sure their crew has the right training and PPE.

- Workers and Apprentices: They have a duty to follow the safety rules, report any hazards or incidents the moment they see them, and use all equipment and PPE correctly.

By clearly assigning these duties, you build a system of accountability. It makes it crystal clear that safety isn't just one person's job. It's a shared responsibility across the entire company.

Hazard and Risk Management Procedures

This section details how you will identify, assess, and control hazards. It’s the engine room of your policy, outlining the practical steps your team will take to stay safe. This includes your process for risk assessments before a new job kicks off or when new machinery is brought in.

For example, a procedure for "working with heavy machinery" in a manufacturing plant should spell out:

- Pre-start Checks: A mandatory daily checklist for every piece of equipment.

- Operator Competency: Clear rules stating only trained and authorised people can operate specific machines.

- Lockout/Tagout: A step-by-step process for isolating machinery during maintenance to prevent accidental start-up.

- Guarding: A non-negotiable requirement that all machine guards must be in place and working before operation.

The aim is to move beyond simply saying "be safe" and provide concrete instructions. If you need a solid framework to start with, using a well-structured WHS policy template can give you the core components you need to tailor to your specific workplace.

Your policy document should be a living tool, not a static one. It needs to reflect the real hazards your team faces, from the physical dangers of a construction site to the less visible risks that impact wellbeing.

Speaking of which, it's crucial to cover the full spectrum of workplace risks. In 2023-24, Australian workers lodged 146,700 serious compensation claims. While many involved physical injuries, a significant number were related to mental stress, showing how important it is for policies to address both physical and psychological safety. You can discover more insights about these workplace safety statistics.

A well-structured policy is your first line of defence. The table below outlines the essential components you'll want to include to make sure your document is comprehensive and clear for everyone.

Essential Components of a Health and Safety Policy

| Component | What It Should Cover | Practical Example (Construction/Manufacturing) |

|---|---|---|

| Policy Statement | A clear declaration of commitment to safety from top management. | "We are committed to zero harm by managing high-risk activities like working at heights and ensuring all machinery is operated safely." |

| Roles & Responsibilities | Who is accountable for what, from directors to frontline workers. | Supervisor: "Responsible for conducting daily toolbox talks and verifying all SWMS are in place before high-risk work begins." |

| Hazard Management | The process for identifying, assessing, and controlling risks (e.g., risk assessments, SWMS). | A detailed procedure for conducting a Job Safety Analysis (JSA) before any non-routine task is performed on the factory floor. |

| Incident Reporting | Clear steps for reporting accidents, injuries, and near misses. | "All incidents, no matter how minor, must be reported to the site foreman immediately and logged in Safety Space within one hour." |

| Emergency Procedures | Evacuation plans, first aid contacts, and response actions for fires, spills, etc. | Site-specific evacuation maps posted at all exits and a list of trained first aid officers with their contact numbers. |

| Training & Competency | Requirements for inductions, specific job training, and qualifications. | "All forklift operators must hold a current High-Risk Work Licence and complete our internal competency assessment annually." |

| Consultation | How you will consult with workers on safety matters (e.g., safety committees, meetings). | "Monthly Health and Safety Committee meetings will be held with representatives from each team to review hazards and incidents." |

| Review & Improvement | A commitment to regularly review and update the policy. | "This policy will be formally reviewed every 12 months or after any significant incident to ensure it remains effective." |

Having these sections clearly laid out ensures nothing gets missed and provides a go-to resource for your entire team. It turns your policy from a document into a daily tool.

Tailoring Policies for High-Risk Industries

A generic, off-the-shelf safety document is practically useless on a construction site or in a manufacturing plant. These environments are dynamic and filled with specific, high-stakes risks. Your health and safety policies can't just be theoretical; they must be grounded in the real challenges your team faces every day, from noisy machinery to busy work sites with multiple subcontractors.

Simply stating a commitment to safety isn't enough. An effective policy for a high-risk industry translates broad principles into specific, enforceable rules that workers can actually understand and follow. It’s all about moving from "be safe" to "this is how we stay safe here."

Manufacturing-Specific Policies

On a factory floor, hazards are constant and often concentrated. A one-size-fits-all approach completely misses the critical details that prevent serious incidents. Your policies have to speak directly to the unique equipment and processes of your operation.

For any manufacturing business, these three areas are absolutely non-negotiable:

- Machine Guarding: Policies must be absolute. State clearly that no machine can be operated if its safety guards are missing, damaged, or disabled. The policy also needs to specify who is authorised to remove guards for maintenance and outline the exact lock-out procedure for doing so safely.

- Lockout/Tagout (LOTO) Procedures: This can't be a vague guideline. Your policy must detail the step-by-step process for isolating energy sources before any maintenance or cleaning begins. It needs to define who is authorised to perform LOTO and require verification before a single tool is picked up.

- Chemical Handling: Your policy needs to cover everything from storage to disposal. It should mandate easy access to Safety Data Sheets (SDS), specify the required Personal Protective Equipment (PPE) for different substances, and outline clear emergency procedures for spills or exposure.

When designing your workspace, it's also smart to consider expert insights on implementing an OSHA-compliant warehouse design. This proactive approach can eliminate many hazards before they ever become a daily risk for your team.

Construction Site Policies

Construction sites are uniquely challenging. They’re constantly changing, and you've got multiple contractors all working in the same space. Your health and safety policies must be adaptable and robust enough to manage this complexity.

For construction, you'll want to focus on key areas like these:

- Working from Heights: Your policy should go beyond just requiring fall protection. It must specify the type of equipment for different tasks (e.g., scaffolding, boom lifts, harnesses), detail inspection requirements for that gear, and establish clear rules for creating exclusion zones below.

- Excavation and Trenching: This is a high-risk activity that demands a detailed policy. Rules must cover soil assessment, mandatory shoring or benching for trenches over a certain depth, and daily inspections by a competent person before anyone enters an excavation.

- Subcontractor Management: Your policy has to apply to everyone on site, not just your direct employees. It should require all subcontractors to provide their Safe Work Method Statements (SWMS) for review, attend site inductions, and participate in your daily toolbox talks. This is how you ensure a consistent standard of safety across the entire project.

Case Study Example: Policy for a Precast Concrete Yard

A precast yard mixes manufacturing and construction risks. A specific policy might state: "All personnel within 5 metres of a crane lift must wear a hard hat and high-vis clothing. No exceptions." This is a simple, measurable, and enforceable rule that directly addresses a common site hazard, turning a general principle ("be aware of overhead loads") into a concrete action.

Using Digital Platforms for Site-Specific Policies

Managing policies across multiple projects with paper and spreadsheets is a nightmare. A digital system is essential for keeping things organised and ensuring the right information gets to the right people.

Think about it. With a platform like Safety Space, you can create a core set of company-wide health and safety policies and then easily add site-specific rules for each project. A supervisor on Project A sees the policies related to their site's deep excavation, while a manager at the fabrication workshop sees the updated rules for the new welding equipment.

This approach makes compliance straightforward. You can distribute updates instantly, track acknowledgements to see who has read the new policies, and store everything in one central, accessible location. It removes confusion and makes sure everyone is working from the most current information.

For those building their policies from the ground up, starting with a comprehensive policies and procedure template can provide a really strong foundation to build upon.

Getting Your New Policies Off the Page and Onto the Site

You’ve put in the hard work to write a solid health and safety policy. That’s a huge step, but let's be honest, a document sitting in a folder has never stopped an incident. The real work begins now: getting that policy into the hands and minds of your team.

A policy is only worth something if every single person knows it, gets it, and actually follows it on the job. This is where a clear, straightforward rollout plan is non-negotiable. Whether it's the office staff or the crew on the tools, everyone needs to be on the same page. A clumsy rollout breeds confusion, pushback, and ultimately, a policy that nobody follows.

Making Training Stick

Death by PowerPoint in a stuffy demountable? That’s the quickest way to get your team to switch off. For safety training to actually work, it needs to be practical, hands-on, and directly tied to the jobs your people do every day. People learn by doing, not just by listening.

Instead of just talking about a new lockout/tagout procedure, get the team out to the machine. Walk them through isolating the power, applying their lock, and testing for zero energy. That’s how you make a procedure real and memorable.

Here are a few ways to keep your training sessions practical and effective:

- Toolbox Talks: These are gold. Use these short, regular catch-ups to focus on one specific part of a new policy. Monday’s talk could be all about the new rules for inspecting harnesses before working at height. Simple, focused, done.

- Visual Guides: A picture is worth a thousand words, especially on a noisy site. Create simple, one-page posters with clear diagrams for critical procedures. A visual guide for chemical handling beats a dense paragraph of text every single time.

- Supervisor-Led Sessions: Your supervisors and foremen need to lead this. When they run the training, it shows everyone that leadership is taking this seriously. It also gives them ownership of safety within their own crews, which is exactly what you want.

The point of training isn’t just ticking a compliance box. It’s about building confidence. You want every worker to know exactly what to do to stay safe without having to second-guess themselves in a critical moment.

Ditch the Paperwork and Go Digital

Trying to manage policy rollouts and training records with paper and spreadsheets is a nightmare. You’re left guessing who’s read what, who’s been trained, and where the sign-off sheets have ended up. This is where a digital system stops being a nice-to-have and becomes an absolute essential.

Using a platform like Safety Space takes that administrative headache away and gives you a clean, auditable trail. You can push out new health and safety policies to every person in the company instantly, no matter if they’re in the head office or on a remote site.

The difference is night and day:

- Instant Distribution: Policy updated? Push it out to everyone’s phone or tablet in seconds. No more printing stacks of paper or waiting for them to be handed out.

- Digital Acknowledgement: You can require workers to digitally sign off that they’ve read and understood a new policy. This gives you a live look at who’s up to speed and who needs a nudge.

- Centralised Training Records: Every training record is stored in one secure spot. When a regulator asks for proof of training, you can pull it up in moments instead of spending hours digging through filing cabinets.

This approach changes your rollout from a logistical mess into a smooth, manageable process. It ensures everyone gets the same message and gives you a clear picture of compliance at all times, freeing you up to focus on what actually matters, keeping your people safe.

Monitoring Your Policies and Making Improvements

Even the best health and safety policies can become outdated. Work processes change, new gear gets rolled out, and risks you never anticipated can pop up. A policy isn't a "set and forget" document you file away; it's a living tool that needs regular check-ups to make sure it’s still protecting your team.

The trick is building a simple but effective system for monitoring and improving your policies. You want to catch weaknesses and spot trends before they turn into a serious incident. It’s all about being proactive, not just reacting after the fact, and using real-world data from your sites to make practical changes.

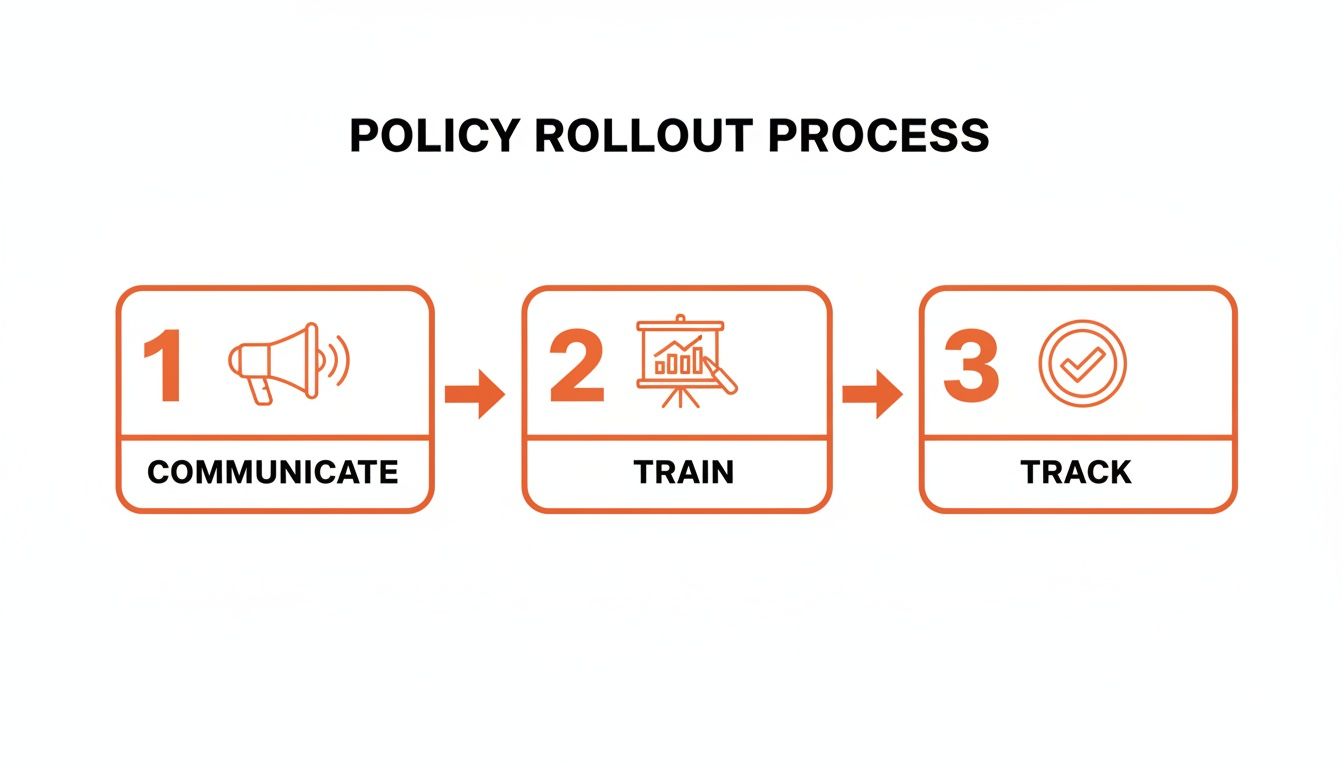

This isn't about bureaucracy. It's about a continuous loop: communicate, train, and track.

As you can see, this isn't a one-off task. Each part of the cycle feeds the next, creating a constant stream of feedback that keeps your policies sharp and relevant.

What Data Should You Monitor?

To figure out if your policies are actually working, you need to look at the right information. This doesn't mean getting lost in complicated spreadsheets. It’s about tuning into the signals your workplace is already sending you.

Here are the gold mines of information:

- Incident Reports: This one’s a no-brainer. Every single incident, no matter how small, is a red flag that a control measure didn't work. A solid investigation should always ask: "Could a better policy or procedure have stopped this from happening?"

- Near Miss Reports: This is your golden ticket. A near miss is a free lesson, a warning shot. When someone reports a close call, it’s a clear signal that there's a gap in one of your policies that needs plugging before it leads to an actual injury.

- Workplace Inspections and Audits: Regular site walkthroughs are non-negotiable. These aren't just for spotting obvious hazards like a blocked fire exit; they're your chance to see if people are actually following the procedures laid out in your health and safety policies.

- Worker Feedback: Your team on the ground sees what’s really going on. Toolbox talks, safety meetings, or even just a casual chat are invaluable for hearing what’s working and what’s a pain point.

Turning Data Into Action

Collecting all this information is useless if it just sits there. The real work starts when you look for patterns. A single near miss could be a fluke, but three near misses with the same bit of machinery in one month? That’s a trend you can't ignore.

Imagine your reports show a spike in workers almost getting hit by forklifts in the main warehouse. That’s a direct signal that your traffic management policy is falling short. The data pinpoints the exact problem you need to solve.

Your goal isn't to assign blame but to understand the "why" behind the data. A recurring issue often points to a flaw in the system or the policy itself, not just an individual mistake.

Effective monitoring also means being prepared for when things do go wrong. Having strong security incident response planning in place is crucial. It gives you a structured way to handle issues immediately and, more importantly, learn from them so they don’t happen again.

Creating a Feedback Loop for Improvement

Once you’ve found a weakness, it's time to close the loop. This means updating the policy, communicating the change clearly, and providing any training needed to get everyone up to speed. This process should be straightforward and consistent.

Here’s what that feedback loop looks like in the real world:

- Identify the Trend: During site inspections, you notice crews are skipping the full lockout/tagout procedure for minor machine adjustments.

- Investigate the Cause: You chat with the maintenance team. They tell you the current procedure is too complex and slow for quick, simple jobs.

- Update the Policy: You collaborate with them to develop a simplified, clearer lockout process for these minor tasks that is still safe but far more practical.

- Communicate and Train: You run a hands-on training session for all maintenance staff, demonstrating the new procedure on the actual equipment.

- Monitor the Change: Over the next few months, you specifically check for compliance with the new procedure during inspections to make sure it's being followed and is actually working.

This cycle of review and improvement ensures your health and safety policies don’t just sit on a shelf. They adapt and stay effective. This is where a digital platform like Safety Space can make a huge difference. You can track incidents, manage inspections, and push out updated policies instantly, all from one central hub. It creates a seamless flow where data from the worksite directly informs and improves the rules that keep everyone safe.

Got Questions About Your Health and Safety Policies?

When you're putting together a health and safety policy, or dusting one off for a review, a few common questions always seem to pop up. Getting these right is the key to creating a document that your team will actually use, rather than one that just gathers dust.

Let's clear up some of the most common points of confusion.

How Often Should We Review Our Health and Safety Policies?

As a rule of thumb, give your policies a formal review at least once a year. But don't just lock it in the calendar and forget about it. A policy is a living document. It needs to change when your workplace changes.

You’ll need to do an immediate review whenever something significant happens. For instance:

- You get new machinery: That new press brake on the factory floor brings a whole new set of risks your old policy couldn't possibly have anticipated.

- You change a work process: Moving from on-site fabrication to using prefabricated modules completely changes the risk profile for your construction team.

- You have an incident or a near-miss: A close call is a massive red flag. It’s a clear signal that there's a gap in your system that needs to be plugged right now.

Think of it this way: regular reviews keep your policies grounded in the reality of your site, not stuck in the past.

What Is the Difference Between a Policy and a Procedure?

This one trips a lot of people up, but it’s actually pretty simple. A policy is the 'what' and 'why', while a procedure is the 'how'.

Your health and safety policy sets out the big picture. It’s a high-level statement of intent. For example, a policy might state, "We are committed to preventing all falls from height on our construction sites." It establishes the goal.

A procedure, like a Safe Work Method Statement (SWMS), is the detailed, step-by-step guide to achieving that goal. It would lay out the exact process for erecting scaffolding, inspecting a harness, and setting up an exclusion zone. Policies set the rules; procedures explain how your team plays the game safely.

Who Is Legally Responsible for the Policies on Site?

In Australia, the Person Conducting a Business or Undertaking (PCBU), which is usually the company itself, holds the primary duty of care. But responsibility for safety isn't just one person's job; it's shared across the entire organization.

It's a chain of responsibility, and it's only as strong as its weakest link.

Responsibility for safety is layered. Directors must ensure the right systems and resources are in place, supervisors must enforce the rules on the ground, and workers must follow them. A failure at any level can lead to a breach.

Here’s how it generally breaks down:

- Officers (like directors): They need to show due diligence. This means they can’t just sign off on a policy; they have to actively ensure the company has the right processes in place and is actually using them.

- Managers and Supervisors: These are the people on the front line. They're responsible for implementing the policies day-to-day, whether that's on the factory floor or out on site.

- Workers: Every worker has a duty to take reasonable care for their own safety and the safety of others. That means following the policies and procedures without taking shortcuts.

Are Policy Templates a Good Idea?

Templates can be a great starting point, but they are never the final product. For high-risk industries like manufacturing or construction, a generic template you pull from the internet is next to useless on its own. It won't know about your specific machinery, your site layout, or the unique risks your team faces every day.

Use a template as a skeleton. It helps ensure you've covered all the essential sections. From there, it's your job to add the muscle, the specific details that make the policy relevant to your workplace. A policy that works is one that reflects reality.

Ready to build health and safety policies that are practical, compliant, and easy to manage? Safety Space replaces paperwork and confusing spreadsheets with one straightforward platform. Book a free demo today to see how you can manage everything from incident reports to training records, all in one place.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.