So, what do we actually mean when we talk about "safe workplace solutions"?

These aren't policies collecting dust on a shelf or some vague safety goal. They are the tangible tools, systems, and procedures you put in place to stop incidents, injuries, and fatalities before they happen. It’s about the practical actions you take to make a worksite physically safer, from installing a guard rail to providing the right kind of breathing apparatus.

The core idea is to actively remove or control hazards before anyone can get hurt.

What Are Practical Safe Workplace Solutions?

Practical safe workplace solutions are the specific, real-world measures that protect your people on the ground. Think of it less like an abstract rulebook and more like a toolbox filled with different methods to tackle different risks.

In high-risk environments like construction and manufacturing, these solutions are the very foundation of a safe, functional, and compliant operation. They're not just about reacting after an incident; they are proactive steps designed to identify potential dangers and systematically control them.

The goal is to build safety directly into the work process itself. This is far more effective than just relying on workers to remember complex safety rules in the middle of a demanding task.

A Framework for Making Safety Decisions

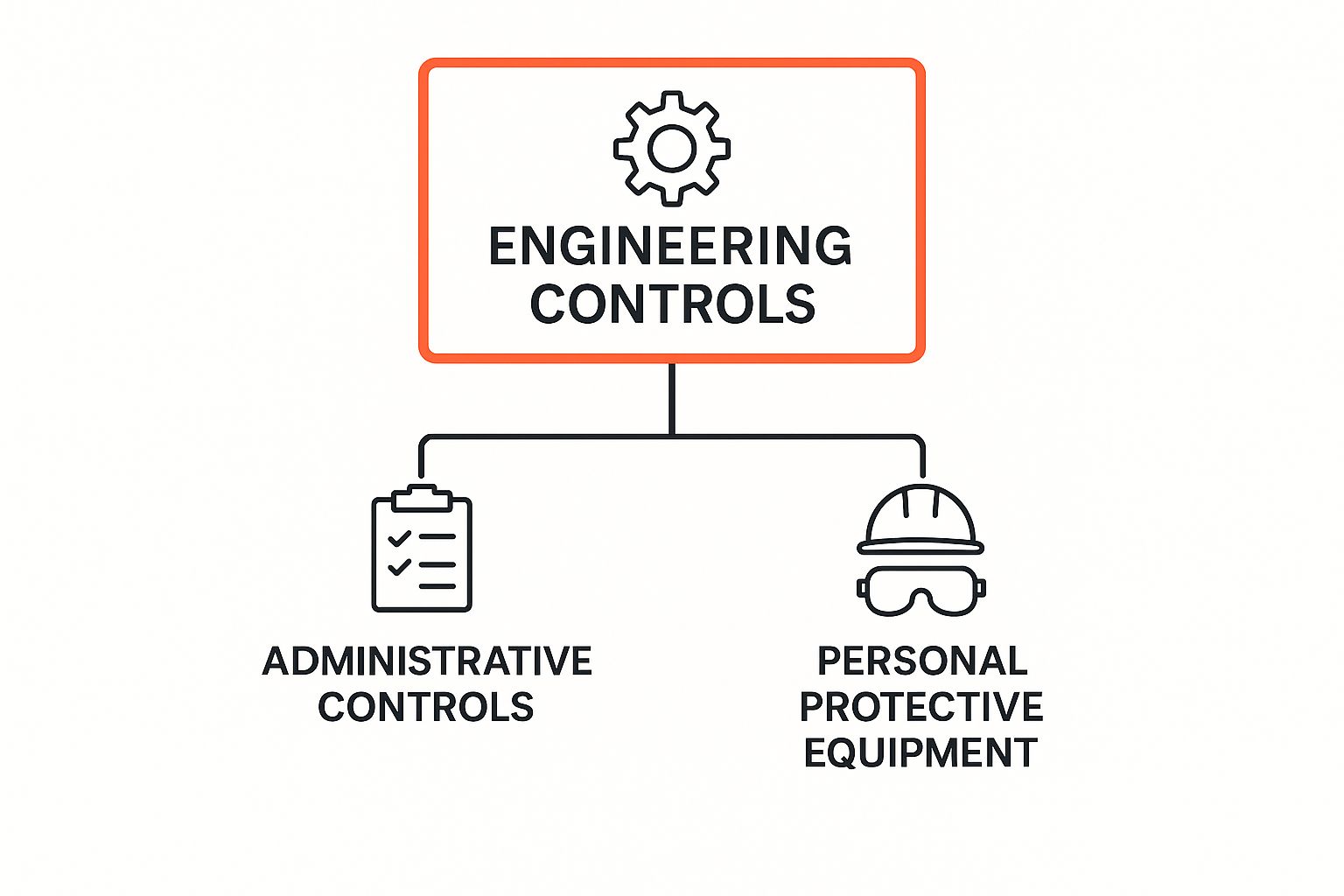

A simple and incredibly effective way to think about implementing these solutions is by using the Hierarchy of Controls. This isn't just a textbook theory; it's a practical guide that helps you choose the most effective safety measure for any given hazard. It ranks different types of controls from most to least reliable, helping you make smarter, more protective decisions.

Essentially, the hierarchy prioritises controls that physically remove the hazard over those that only protect the individual worker. This visual guide lays out the main categories, ordered from the most effective down to the least.

As you can see, the most reliable solutions are engineered into the environment itself, while those that rely on individual human action are considered the last line of defence.

To make this crystal clear, let's break down the hierarchy with some real-world examples you might see on a factory floor.

The Hierarchy of Workplace Safety Controls

| Control Level | Description | Example |

|---|---|---|

| Elimination | Physically removing the hazard entirely from the workplace. The most effective control. | Instead of workers manually lifting heavy boxes, introduce an automated conveyor system to move them. The manual handling risk is gone. |

| Substitution | Replacing a hazardous substance, process, or material with a less hazardous one. | Switching from a toxic solvent-based paint to a safer water-based alternative. |

| Engineering | Isolating people from the hazard by creating a physical barrier or redesigning the equipment. | Installing a guard on a cutting machine to prevent hand injuries or adding a local exhaust ventilation system to capture harmful dust at the source. |

| Administration | Changing the way people work through procedures, training, or signage. | Implementing safe work procedures for operating machinery, limiting exposure time to a noisy area, or putting up warning signs. |

| PPE | Providing workers with Personal Protective Equipment to protect them from the hazard. The least effective, last resort. | Requiring workers to wear safety glasses, hard hats, gloves, or respirators. |

This table shows a clear path: always aim for the highest level of control possible before moving down the list.

Why This Practical Approach Matters

Focusing on tangible, higher-level solutions creates a far more resilient safety system. A machine guard, for instance, works 24/7 without needing a reminder or a coffee break.

In contrast, relying solely on a rule that tells workers to "be careful" requires constant attention and is much more prone to human error, especially during a busy production run or a complex construction phase.

The most dependable safety measures are those that work automatically to separate people from harm. They are designed into the job, not just added on as an afterthought.

Ultimately, effective workplace solutions are about making the safe way of working the easiest and most logical way of working. By applying this practical framework, businesses can move beyond just ticking compliance boxes and start building a genuinely safer environment for everyone. This approach isn't just better for protecting your team; it's essential for maintaining productivity and operational stability.

Using Engineering Controls as Your First Line of Defence

When you’re trying to build a genuinely safe workplace, the best solutions are the ones that work on their own, almost invisibly. That's the whole idea behind engineering controls. These are physical changes you make to the work environment, equipment, or processes that put a barrier between your workers and the hazards they face.

Think of them as permanent fixes that don’t rely on someone remembering a rule or following a procedure perfectly every single time. Instead of depending on human action, these controls build safety right into the job itself. It’s what makes them your most reliable line of defence.

The principle is simple: design the hazard out of the picture entirely. Physically separating people from danger is always going to be more effective than just asking them to be careful around it.

Practical Examples in Australian Industries

Engineering controls aren't just abstract theories; they're the practical, physical solutions you see on worksites all over Australia. They're the silent protectors that stop incidents before they even have a chance to happen.

Here are a few common examples you’d find in high-risk sectors like manufacturing and construction:

- Machine Guarding: This is about fitting fixed guards or shields around the moving parts of machinery like saws, presses, or conveyors. It creates a simple physical barrier that prevents hands, clothing, or tools from getting snagged.

- Ventilation Systems: You might install a local exhaust ventilation (LEV) system right where welding fumes, chemical vapours, or hazardous dust is being created. It sucks up contaminants at the source before they ever reach a worker's breathing zone.

- Guardrails and Barriers: This is as straightforward as erecting sturdy guardrails on elevated platforms, scaffolding, and open-sided floors. This is what we call passive fall protection. It’s always there, unlike a safety harness that has to be actively put on and used correctly.

These types of safe workplace solutions are so effective because they function with little to no ongoing input from the worker. A guardrail protects everyone, whether they're having a good day or a bad day, trained or untrained. This reliability is what makes engineering controls the bedrock of any solid safety system.

Modernising Safety with Advanced Controls

Technology has opened up a whole new world of possibilities for engineering controls, taking us beyond simple physical barriers to more sophisticated systems. These modern solutions use automation and smart design to prevent injuries with incredible precision.

Manual handling is a massive area of concern and a leading cause of musculoskeletal disorders. Using ergonomic lifters, hoists, or even robotic arms to move heavy materials takes the physical strain off workers completely, tackling the root cause of the injury head-on.

Another key area is equipment operation. Think about automated shut-off systems that use sensors to detect when a person enters a danger zone and immediately stop the machine. These systems react faster than any human possibly could, providing a foolproof safety net.

The best engineering controls make the safe way to do a job the only way to do a job. They remove the potential for human error by taking the decision out of the worker's hands.

And it’s not just for heavy industry. For roles that involve a lot of sitting, a critical engineering control is ensuring a proper ergonomic setup for desk work to prevent long-term strain. Even in an office, redesigning the workspace itself is a powerful protective measure.

The Impact of Getting It Right

Putting effective engineering controls in place isn't just about ticking a compliance box; it's about fundamentally reducing the risk of someone getting seriously hurt. The statistics show us exactly where the biggest risks are and why these physical solutions are so vital.

According to Safe Work Australia, there were 200 workplace fatalities in a recent year, up from 195. Vehicle incidents were the leading cause, but falls from height saw a shocking 71% increase. The sobering reality is that over three-quarters of these deaths happened in just six industries, including construction and manufacturing. That tells us exactly where we need to focus.

This data makes a clear case. Installing robust guardrails directly addresses that huge spike in fall-related deaths. Using automated vehicles or improving traffic management plans in a factory tackles the number one cause of workplace fatalities. These aren't minor tweaks; they're life-saving interventions that offer the highest level of protection possible. By prioritising engineering controls, businesses can create an environment where safety is truly built-in, not just bolted on as an afterthought.

Implementing Administrative Controls and Safe Work Procedures

While engineering controls physically change the workplace, administrative controls change how people work within that space. These are your rules, procedures, and training programs that guide day-to-day tasks.

Think of them as the operating manual for a safe worksite. They direct the flow of work and people to sidestep risks that can’t be completely engineered out.

These controls are absolutely essential because they tackle the human element of safety head-on. They set clear, consistent expectations for how things get done, especially when hazards are still present. It’s all about creating smart, repeatable processes that just become the standard way of operating.

But getting these procedures right is critical. Vague or inconsistent rules can cause more confusion than safety. Clarity is everything.

Building Procedures That Actually Work

The best administrative controls are specific, easy to understand, and directly relevant to the job. A general rule like "be careful with machinery" is useless. A strong administrative control provides a step-by-step process that leaves no room for guesswork.

Here are a few real-world examples you’d see on a construction site or in a factory:

- Lockout/Tagout (LOTO) Procedures: This isn't just a suggestion; it's a formal process for shutting down machinery before anyone gets near it for maintenance. A solid LOTO procedure spells out who is authorised, the exact sequence for cutting power, how to verify the machine is dead, and the steps for safely firing it back up.

- Traffic Management Plans: On a busy construction site, you can't just hope for the best. A detailed plan is needed to coordinate vehicles, equipment, and people. This includes things like designated walkways, speed limits for forklifts, clear rules for reversing, and communication protocols between drivers and spotters.

- Scheduling High-Risk Work: Sometimes, the simplest control is the most effective. Scheduling "hot work" like welding or grinding for cooler parts of the day is a smart move. It directly reduces the risk of heat stress and the fatigue-related mistakes that come with it.

These procedures give high-risk activities a predictable structure, making safety a deliberate part of the workflow, not an afterthought.

The whole point of a safe work procedure is to make the safe way to do a job the only way it gets done. It standardises actions to stop people from taking shortcuts or making bad calls when the pressure is on.

The best way to develop these processes is with input from the workers who will actually be using them. Their firsthand knowledge is gold when it comes to creating rules that are practical, not just compliant on paper. To get it right, it's worth learning how to create a safe work procedure that your team will actually follow.

Your Procedures Aren't Set in Stone

Workplaces are always changing. New equipment comes in, teams evolve, and site conditions shift. Because of this, your administrative controls and safe work procedures can't be a "set and forget" exercise. They have to be living documents.

A procedure that was perfect last year might be useless or even dangerous today if a process has changed. Regular reviews make sure your safety rules stay relevant and effective.

Think about a few obvious triggers for reviewing your procedures:

- After an Incident or Near Miss: Any safety event is a massive red flag that a procedure might have failed. Investigating what happened should always include a hard look at the related work procedure to find and fix any gaps.

- When New Gear Arrives: A new machine or tool will almost certainly need a new or updated safe work procedure. It has its own unique hazards and operating quirks that need to be documented.

- During Regular Safety Audits: Don't wait for something to go wrong. Proactively schedule reviews of all high-risk procedures, even if there haven't been any incidents. This helps you catch problems before they lead to an injury.

And remember, consistency is just as important as the rules themselves. If a procedure is enforced one week but ignored the next, it loses all credibility. For these controls to work, they have to be consistently applied and understood by everyone on site, from the boss to the newest person on the crew.

Personal Protective Equipment as a Final Barrier

So, you’ve installed all the physical guards and rolled out the safest possible procedures. But what about the risk that’s left over? That’s where Personal Protective Equipment (PPE) comes into the picture. It’s the final barrier between a worker and a potential hazard, and it's absolutely vital to get its role right.

Think of PPE like the seatbelt in your car. A seatbelt is non-negotiable and can save your life, but it’s not the first thing you rely on for a safe journey. Before the seatbelt comes into play, you have brakes, airbags, and the structural integrity of the car itself. The seatbelt is your last resort if all those other systems fail to prevent an accident.

It’s the exact same principle on a worksite. PPE is a critical last-ditch effort. It doesn't actually remove the hazard; it just provides a shield. This is why it sits at the bottom of the hierarchy of controls. A machine guard protects everyone automatically, but PPE only protects the person wearing it. And only if it’s worn perfectly, every single time.

Going Beyond a Simple Checklist

A successful PPE program is so much more than just handing out hard hats and hi-vis vests on day one. To be truly effective, it needs to be a complete system built with careful thought and constant management. Just having the gear on site doesn't automatically create a safe workplace solution.

A robust program is built on a few practical pillars:

- Correct Selection: There’s no such thing as "one-size-fits-all" here. The specific PPE must be matched precisely to the specific hazard your team is facing.

- Proper Fit and Comfort: If a respirator doesn’t create a proper seal or safety glasses keep fogging up, they’re not doing their job. Gear that’s uncomfortable or fits poorly is also far more likely to be taken off.

- Thorough Training: Your team needs to know more than just what to wear. They need to understand how to wear it, how to inspect it for damage, how to clean it, and crucially, when it’s time for a replacement.

- Consistent Enforcement: The rules for wearing PPE have to apply to everyone, from the newest apprentice right up to the site manager. No exceptions.

If you let any one of these pillars crumble, the whole PPE strategy can become ineffective. You end up with workers who think they're protected, leaving them exposed to serious risks.

Matching the PPE to the Hazard

Choosing the right equipment is the absolute foundation of your PPE program. Handing someone the wrong type of glove for a specific chemical or the wrong mask for a particular dust can be just as dangerous as giving them nothing at all.

For instance, a standard nuisance dust mask offers zero protection against chemical vapours, and a pair of cotton gloves won’t do a thing against a corrosive liquid. This is why a detailed risk assessment is so critical. It tells you exactly what you need to protect your people from.

The most expensive PPE in the world is useless if it’s the wrong type for the job. The goal isn’t just to provide equipment; it’s to provide the right equipment.

To make this crystal clear, let’s look at how to match the gear to the danger.

Choosing the Right PPE for Common Hazards

Here’s a quick reference guide that maps common industrial hazards to the kind of PPE you'll need. Think of it as a starting point for building out your site-specific requirements.

| Hazard | Primary PPE | Secondary PPE (If applicable) |

|---|---|---|

| Falling Objects | Hard Hat | Steel-Capped Boots |

| Airborne Dust/Silica | P2/N95 Respirator | Safety Goggles |

| Welding Fumes | Welding Helmet with Respirator | Fire-Resistant Clothing |

| Loud Machinery | Earmuffs or Earplugs | - |

| Chemical Splashes | Chemical Goggles | Face Shield, Chemical-Resistant Gloves |

| Low Visibility Areas | High-Visibility Vest/Clothing | - |

As you can see, a single task often requires multiple pieces of PPE working in concert to provide full protection. Someone cutting concrete, for example, needs a respirator for the silica dust and safety goggles to shield their eyes from flying debris. Each piece of equipment serves a distinct and critical purpose as that final, necessary line of defence.

Using Safety Software to Manage Workplace Risk

If you’re still wrestling with stacks of paper, scattered spreadsheets, and clunky old systems, you’re missing a huge opportunity to build genuinely safe workplace solutions. Modern safety management software isn’t just another tool; it’s a central hub that brings all your critical safety information into one organised, digital space.

Think of it less as adding another layer of complexity and more as simplifying how you track, manage, and actually act on safety information across your entire operation. A digital approach gives you real-time visibility that paper-based systems simply can't compete with.

Instead of chasing down an incident report or wondering if a corrective action was ever completed, you get a clear, immediate picture of your safety performance. This is the crucial shift from being reactive to proactive, and it’s what stops small issues from spiralling into serious incidents.

From Paper Chaos to Digital Clarity

The real power of safety software isn't just in digitising forms; it's in its ability to connect all the different moving parts of your safety program. You move from isolated documents to an interconnected system where information flows exactly where it needs to.

This digital approach offers direct, practical benefits for managing risk on any worksite, but it’s an absolute game-changer in fast-paced environments like manufacturing or construction.

Here’s what that looks like in practice:

- Centralised Incident Reporting: Every incident report is logged in one place, making it incredibly easy to see what happened, where it happened, and why. No more lost paperwork.

- Corrective Action Tracking: When a hazard is identified, a corrective action is assigned to a specific person with a deadline. The system follows up until it’s done, ensuring nothing falls through the cracks.

- Training Record Management: Keep a live, up-to-date digital record of all employee training and certifications, with automatic reminders for when refreshers are due.

- Digital Site Inspections: Supervisors can conduct inspections on a tablet right from the field, attaching photos of hazards and generating reports instantly.

These features work together to create a single source of truth for your safety program, eliminating confusion and guesswork.

By connecting your safety data, you can start to spot patterns and trends. Recurring issues that might have been missed in a paper system become obvious, allowing you to fix the root cause before it leads to a serious injury.

This is where platforms like Safety Space give you a serious advantage. They offer a clear overview of your safety performance, helping managers pinpoint problem areas and roll out targeted improvements. You can learn more by exploring our detailed guide on health and safety management software.

A Real-World Scenario in Action

Let’s make this real. Imagine a supervisor walking through a busy manufacturing plant. She spots an oil leak near a walkway, a classic but serious slip hazard.

In a traditional paper-based system, her next steps are a pain. She has to find the right form, fill it out by hand, and then walk it over to the safety manager's office. That form might sit in an inbox for a day or two before anyone even sees it. Tracking the repair means more follow-up emails and phone calls.

Now, picture the same scene with safety software. The supervisor pulls out her tablet, opens the safety app, and logs the hazard in under a minute. She snaps a photo of the leak, marks its exact location on a site map, and assigns a corrective action directly to a maintenance team member with a clear deadline. The system automatically notifies the maintenance worker and sends reminders until the job is marked as complete. The entire process is documented, tracked, and visible to everyone who needs to know, all in real time.

This instant, accountable workflow is one of the most powerful safe workplace solutions available today. Of course, even the best software needs a solid foundation, which is why implementing robust risk management best practices remains essential.

Using Data to Prevent Future Incidents

The ongoing challenge of workplace safety in Australia underscores just how badly we need better systems. With 32 worker deaths recorded early in one recent year and 168 fatalities the year prior, it’s clear that traditional methods aren’t enough to get ahead of persistent risks. These aren't just numbers; they represent common failures in risk assessment and follow-through that lead to preventable tragedies.

Safety software directly addresses this gap by creating an organised, data-driven approach to safety. It helps businesses move beyond just ticking compliance boxes to actively managing risk, giving them the tools to not only fix today's problems but also predict and prevent tomorrow's.

How to Address Psychosocial Hazards at Work

A truly safe workplace goes way beyond just preventing trips, falls, or machinery accidents. It’s also about tackling the hidden dangers, the parts of work that can cause real psychological harm. We call these psychosocial hazards, and they're a massive, growing focus for any business that's serious about safety.

Put simply, these are the aspects of a job's design, the way work is organised, or the social dynamics that can lead to stress, burnout, and mental distress. This isn't an abstract theory; it's about the real, day-to-day grind.

Overwhelming deadlines, a total lack of support from supervisors, constant workplace conflict, or having to deal with aggressive customers are all serious psychosocial hazards. And ignoring them doesn't just hurt someone's wellbeing; it has a direct, tangible impact on physical safety.

The Link Between Mental and Physical Safety

Think about it. When a worker is stressed, exhausted, or completely burnt out, where is their focus? It's certainly not 100% on the task at hand.

That drop in concentration can lead to critical, devastating mistakes when operating machinery, working at heights, or handling hazardous materials. A worker who is mentally replaying a conflict with their manager is not fully present, and that’s when incidents happen.

Managing these risks isn't some "nice-to-have" add-on. It's a core, non-negotiable part of preventing physical injuries and creating a workplace that's actually safe for everyone.

Practical Steps to Reduce Psychosocial Risks

So, how do you fix it? Tackling these hazards is all about administrative controls. In other words, changing your processes and procedures. The goal is to design work in a way that minimises psychological strain from the get-go.

A recent report on Australian workplaces found that a staggering 65% of workers have faced aggression from customers, while job demands, poor support, and conflict were the top hazards mentioned. Even more telling, only 37% rated their employer’s commitment to safety as 'very good'. That's a huge gap that needs closing. You can read the full report to get the whole picture on the growing safety divide for Australian workers.

Here are a few practical actions you can put in place right now:

- Implement Clear Reporting Procedures: Give your people a straightforward, confidential way to report bullying, harassment, and conflict. They need to trust that their concerns will be taken seriously and handled properly, not swept under the rug.

- Train Your Managers: Get your supervisors and managers skilled up to spot the early signs of distress in their teams. They need to know how to have supportive conversations and, crucially, where to direct people for professional help.

- Establish Support Systems: For any role that involves dealing with difficult customers, create a system for post-incident support. This could be as simple as giving them time off the floor to decompress or ensuring they have easy access to employee assistance programs.

- Manage Workload Realistically: Constantly review workloads and deadlines to make sure they're actually achievable. Unrelenting high pressure is a fast track to burnout, which sends the risk of errors and injuries through the roof.

By putting clear, supportive procedures in place, you are not just ticking a box for mental wellbeing. You are actively reducing the chances of a physical incident caused by distraction or stress.

These kinds of practical, administrative controls are powerful safe workplace solutions. They don't just treat the symptoms; they build a more resilient and focused workforce by tackling the root causes of psychological harm before they can spiral into a safety disaster.

Got Questions About Workplace Safety Solutions?

When you’re looking to bring in new workplace safety solutions, it’s completely normal to have a few questions. It can feel like a huge task, but breaking it down into practical steps makes it much more manageable. Here are some straight answers to the things we hear most often.

Our goal here is to give you the confidence to take the next step, focusing on what will make the biggest difference on your worksites.

Where’s the Best Place to Start?

The best place to start is always with a thorough risk assessment. You can't fix what you don't know is broken. Walk through your site with a critical eye, or even better, use a structured digital inspection tool to make sure nothing gets missed.

Once you’ve pinpointed your key risks, it’s time to prioritise them using the Hierarchy of Controls. Don’t try to boil the ocean. Zero in on the high-impact engineering controls first, the ones that physically remove or reduce the most serious dangers. This targeted approach guarantees your initial efforts deliver the biggest safety payoff.

How Much Is This Going to Cost?

The cost of putting safe workplace solutions in place can vary wildly, and that's the honest truth. A simple administrative control, like writing a new safe work procedure, might only cost you time for development and training.

On the flip side, a major engineering control like installing a new ventilation system is a significant capital investment.

But it’s crucial to weigh that upfront cost against the long-term cost of doing nothing. A single serious injury can trigger direct costs from workers' compensation and a cascade of indirect costs from lost productivity and regulatory fines. These can easily dwarf the initial safety investment. Prevention is almost always cheaper than reaction.

How Do We Get Our Team to Actually Follow New Procedures?

Getting your team on board is everything, and it all starts with involving them. When you’re developing new safe work procedures, bring the workers who will actually be using them into the conversation. They’re the ones on the ground, and they often have the most practical insights into what will and won’t work.

Clear training is also non-negotiable. Don't just hand someone a document and walk away. You need to demonstrate the procedure, explain the why behind it, and make time for questions. The final piece of the puzzle is consistent follow-through from supervisors, ensuring the new safety standard becomes the normal way of working for everyone.

Ready to move beyond paper and messy spreadsheets? The Safety Space platform pulls all your safety management needs into one simple, digital hub. From incident reporting and tracking corrective actions to digital inspections and training management, we give you the tools to build a safer, more compliant workplace. Book your free demo and H&S consultation today to see exactly how it works.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.