Let’s cut to the chase. Safety systems management isn't about ticking boxes or chasing a paper trail for compliance. It’s a practical framework for getting ahead of workplace hazards and stopping incidents before they happen.

Think of it like the blueprints for a high-rise. You wouldn't start construction without a detailed, engineered plan, right? The same logic applies to your worksite. You can't run a safe operation without an organized system holding everything together. It's this systematic approach that keeps work flowing and, most importantly, keeps your people safe.

Understanding the Core of Safety Systems Management

At its heart, safety systems management is a formal process for controlling risk. It’s what shifts safety from a reactive, "fix-it-when-it-breaks" chore to a proactive, integrated part of your business. So, instead of just sticking up a "wet floor" sign after a slip, this approach pushes you to ask why the floor is wet and fix the root cause, like a leaky pipe in the ceiling.

For managers in demanding fields like construction and manufacturing, this method offers a reliable way to spot potential dangers, put solid controls in place, and then check that those controls are working. It’s all about creating repeatable processes that don’t rely on a single person’s memory or good intentions. A well-designed system makes safety predictable and consistent, no matter the shift or the team.

Why a System Is Better Than a Stack of Policies

A binder full of safety rules gathering dust on a shelf is not a system. A real system connects all the individual pieces, the policies, procedures, and people, into a functional whole that ensures nothing gets missed. This organized structure is fundamental for any high-risk industry where the stakes are high.

A system creates a clear, logical structure for how safety is handled, from the site manager right down to the newest apprentice. To give you a better idea of what this looks like, here's a quick breakdown of the core components.

A proper safety management system is built on several key pillars that work together. Without all of them, the structure can become unstable.

| Component | Core Function |

|---|---|

| Risk Assessments | Proactively identifying what could go wrong before it does. |

| Safe Work Procedures | Documenting the one, correct, safe way to perform tasks. |

| Training & Competency | Ensuring everyone has the skills and knowledge to work safely. |

| Monitoring & Reporting | Checking that procedures are being followed and learning from every incident and near miss. |

These elements are designed to reinforce each other, creating a dependable safety framework. If one piece is missing or weak, the whole structure suffers. We go deeper into this in our guide on the 9 key elements of a health and safety management system, which is worth a read.

A safety management system is a business tool for preventing loss. It protects your most valuable assets: your people, your equipment, and your company's reputation.

Ultimately, this isn't about adding an administrative burden. It's a fundamental part of smart business management. It provides a clear, logical roadmap to a safer workplace, which in turn reduces the risk of expensive incidents and operational headaches. It's the difference between hoping your workplace is safe and knowing it is.

The Four Pillars of an Effective Safety System

A robust safety system doesn't just appear out of thin air. It’s built on a solid foundation of four interconnected pillars that all support each other. When one is weak, the entire structure becomes unsteady. Think of it like building a house: you need a strong foundation, solid walls, a protective roof, and regular upkeep. Miss any one of these, and you're asking for trouble.

In safety systems management, these four pillars are Hazard Identification and Risk Assessment, Control Measures, Monitoring and Review, and Documentation and Reporting. Let's break down what each of these means in a practical sense, using real examples from the construction and manufacturing floors where it counts.

Pillar 1: Hazard Identification and Risk Assessment

This is where all good safety management starts. It’s about proactively hunting for what could go wrong, not waiting for an incident to point out the dangers for you. A simple checklist can be a decent start, but real hazard identification requires 'what-if' thinking.

For example, on a construction site, you don't just note the presence of a trench. You ask, "What if the soil is unstable and the walls collapse?" Or, "What if heavy rain floods the area overnight?" This process naturally leads to a risk assessment, where you work out how likely it is for something to go wrong and just how bad the consequences would be.

A risk assessment isn't about creating paperwork; it's about making informed decisions. It tells you which problems to fix first based on their potential to cause serious harm.

In a manufacturing plant, this might involve looking at a new piece of machinery. The obvious hazard is moving parts, of course. But what about the less obvious risks? What if a fluid line ruptures and sprays hot liquid? What if the machine's software glitches and it fails to stop? Identifying these potential issues is the first and most critical step.

Pillar 2: Control Measures

Once you’ve identified your hazards and assessed their risks, the next pillar is putting control measures in place. These are the real-world actions and equipment you use to protect your people. It’s crucial to apply these controls in a specific order, known as the hierarchy of controls.

The goal is to always use the most effective control possible. Here’s how it works, from most effective down to least:

- Elimination: Get rid of the hazard completely. For instance, designing a process so workers don’t have to work at height in the first place.

- Substitution: Swap the hazard for something safer. A classic example is using a less toxic chemical for cleaning parts.

- Engineering Controls: Physically isolate people from the hazard. This is where you see solutions like machine guards on a press or ventilation systems to pull harmful fumes out of the air.

- Administrative Controls: Change the way people work. This includes creating safe work procedures, using job rotation to limit exposure, or putting up warning signs.

- Personal Protective Equipment (PPE): Protect the worker with gear like hard hats, gloves, or respirators. This is always the last line of defence because it doesn't remove the hazard.

Relying only on PPE is a common and dangerous mistake. A machine guard (an engineering control) physically stops a hand from entering a danger zone, whereas gloves (PPE) only lessen the severity of an injury if contact occurs. An effective system always prioritizes the more reliable controls first.

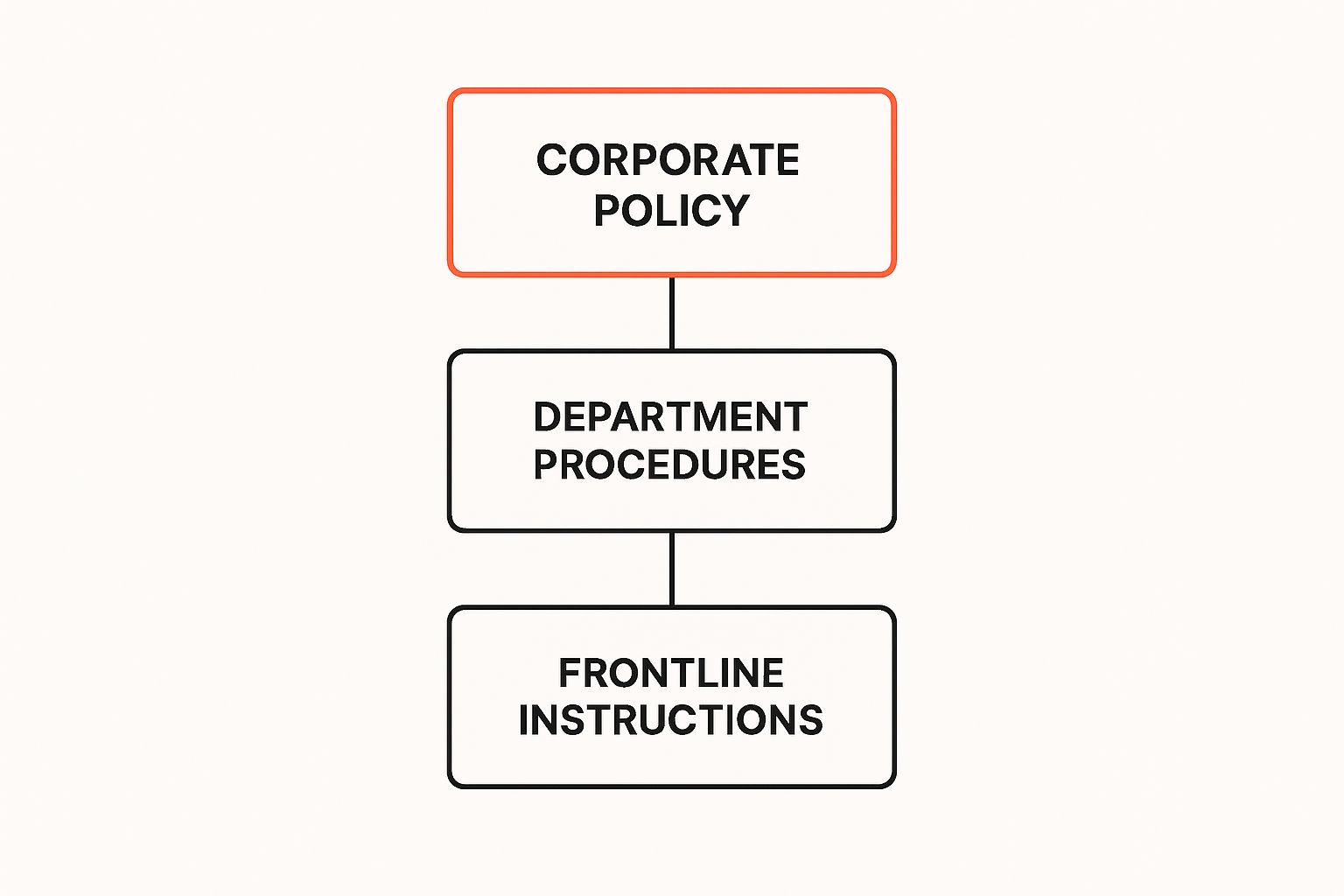

The following diagram shows how safety management flows from high-level corporate goals down to specific instructions for frontline teams.

This hierarchy shows that effective safety systems management requires clear direction at every level to make sure policies are translated into safe actions on the ground.

Pillar 3: Monitoring and Review

A safety system is never a 'set and forget' tool. The third pillar, monitoring and review, is all about actively checking that your control measures are in place and working as intended. This involves more than just a casual walk-through.

This is where you conduct regular site inspections, pre-start equipment checks, and formal safety audits. The key here is to look for problems with the system, not just to blame individuals. If you find that lockout/tagout procedures are consistently being ignored, the question shouldn't be "Why are workers breaking the rules?" It should be "Is our procedure too complicated? Is the training insufficient? Do workers have the time and tools to do it right?"

Australia's proactive approach to workplace safety highlights the value of consistent monitoring. With an estimated 8.4 inspectors per 1,000 employees, regulatory bodies conduct frequent workplace visits aimed at finding and fixing risks before incidents happen. For comparison, that's a higher density than New Zealand's 6.8 inspectors per 1,000 employees. This focus on proactive checks drives better safety outcomes. You can explore more data on these regulatory strategies in this 2024 State of a Thriving Nation report.

Pillar 4: Documentation and Reporting

The final pillar is documentation and reporting. People often see this as the most tedious part, but it's essential for learning, improving, and proving you've done the right thing. Good documentation provides a reliable record of your safety activities and a solid foundation for legal compliance.

This includes things like:

- Incident Reports: Recording what happened, but more importantly, digging into the root causes to prevent it from happening again.

- Inspection Records: Keeping track of what was checked, what was found, and what corrective actions were taken.

- Training Records: Documenting who has been trained on which procedures and when they need a refresher course.

- Safety Meeting Minutes: Capturing the issues discussed, decisions made, and tasks assigned to people.

These records aren't just for auditors. They are invaluable tools for spotting trends. For example, if your incident reports show a pattern of minor hand injuries in one specific area, that’s a clear signal that your hazard assessments or control measures for that task need another look.

Together, these four pillars create a continuous cycle. You identify risks, put controls in place, monitor their effectiveness, and document your findings, which then feeds back into your next round of risk assessments. This systematic process is what makes safety systems management a powerful tool for creating a consistently safe workplace.

How to Implement Your Safety Management System

Putting a safety management system into practice isn't a single, giant leap. It’s a series of deliberate, logical steps. Moving from a plan on paper to a functioning system on the factory floor or construction site requires a clear roadmap.

Each step builds on the last, creating a solid foundation for a system that actively prevents incidents, rather than just reacting to them. Let's walk through the entire process, from getting the initial backing you need to launching and monitoring your new framework.

Step 1: Secure Management Commitment

Before you think about procedures or paperwork, you need genuine commitment from leadership. This is more than just a verbal thumbs-up; it means a real allocation of resources. A budget for new gear, time carved out for proper worker training, and visible support from the top are all non-negotiable.

When management actively champions safety, it sends a strong message through the organization. Workers are far more likely to buy in when they see their supervisors and managers are held to the exact same standards.

- Common Pitfall to Avoid: Don't mistake passive approval for active commitment. If leadership isn't willing to put a budget and dedicated time behind safety, the system will fail before it even starts.

Step 2: Form a Diverse Safety Committee

Next, you need to assemble a team to steer the ship. A safety committee shouldn't just be a top-heavy group of managers. For any system to work, you need insights from the people who face the risks every day.

Pull in people from different departments, shifts, and experience levels. Get a machine operator, a site laborer, a maintenance tech, and a supervisor in the same room. Their ground-level perspective is what makes procedures practical and realistic, not just theoretically correct.

This committee will be the engine room, reviewing risks, developing procedures, and championing the system among their peers. Their involvement creates a sense of ownership that you can't get any other way.

A safety committee is the bridge between management's goals and the reality on the frontline. It makes sure the system is built for the real world, not just for a binder on a shelf.

Step 3: Conduct a Baseline Assessment

You can't map out a journey until you know your starting point. A baseline assessment gives you an honest snapshot of where your safety performance is right now. This isn't about pointing fingers; it's about finding the gaps so you can focus your efforts where they'll make the biggest difference.

Go through your incident records from the last few years. Walk the site with a critical eye, looking specifically for uncontrolled hazards. Most importantly, talk to your people. Ask them what their biggest safety worries are.

- Common Pitfall to Avoid: Be wary of the "tick-and-flick" audit that only checks for surface-level compliance. A proper assessment digs deep to find systemic weaknesses, like inconsistent training or a habit of not closing out corrective actions.

Step 4: Develop Clear Policies and Procedures

With your assessment done, you can start building the core of your safety systems management. This means creating clear, simple, and direct procedures for your most critical tasks. Start with the high-risk activities you already identified, like lockout/tagout, working at heights, or confined space entry.

Get the safety committee and relevant workers involved in writing these procedures. A procedure written by someone who has never done the job is almost always impractical and will be ignored. The goal is to document the one, correct, safe way to get a task done.

Keep the language simple. Use photos, diagrams, and flowcharts wherever you can. A dense, text-heavy document won't get used in a busy, high-pressure environment.

Step 5: Train Your Team Effectively

Once your procedures are documented, it’s time to train everyone. And this means real training. A generic PowerPoint in a stuffy conference room won't cut it. Effective training needs to be hands-on and job-specific.

Take your crew to the actual equipment and have them physically walk through the new lockout procedure. For the team on site, run a practical demo on how to fit and inspect a harness correctly. This kind of active, hands-on learning builds muscle memory and makes sure people get it.

Remember, training isn't a one-off event. You need to plan for regular refreshers and provide extra training anytime a process changes or a new hazard pops up.

- Common Pitfall to Avoid: Don't treat training as a box-ticking exercise. If it's boring, generic, and disconnected from daily work, you've just wasted everyone's time and money.

Step 6: Launch and Monitor Your System

With policies written and your team trained, it's go-time. Announce the official launch date clearly and make sure all your supervisors are ready to lead the change. Those first few weeks are critical for setting new habits.

But the work isn't over at launch. You have to keep a close watch to make sure the system is working. This is where you close the loop, using inspections and observations to verify that the new procedures are being followed and are controlling the risks they were designed for. Regular safety audits are a crucial part of this. For a deeper look, check out our article on the importance of regular safety audits for your business.

Use the data you collect from inspections and incident reports to fine-tune your approach. An effective safety management system is never "finished", it's a living cycle of continuous improvement.

The True Cost of a Reactive Safety Approach

A lot of businesses run on a reactive safety model, often without even realizing it. It’s the classic "if it ain't broke, don't fix it" mindset. An incident happens, a quick fix is applied, and everyone moves on until the next one. This approach feels simpler in the short term, but it traps businesses in a costly and dangerous cycle.

Waiting for an incident before you act isn't a strategy; it's a gamble. The direct costs are easy to see: compensation claims, equipment repairs, and potential fines. But it's the indirect costs that often do the most damage to your bottom line, rippling through the entire operation long after the event itself.

The Problem with Patchwork Fixes

A reactive approach only ever addresses the symptom, not the root cause. Picture a common scenario: a worker slips on a patch of oil on the workshop floor. The reactive fix? Clean the spill and maybe put up a temporary "wet floor" sign. Job done, right?

Not quite. A proper safety systems management approach digs deeper, asking: Why was there oil on the floor in the first place? That question might uncover a slow leak in a machine's hydraulic line, a flawed maintenance schedule, or poor training on how to handle fluids. The sign doesn't fix any of that.

By only cleaning the spill, you're guaranteeing the same problem, or a similar one, will happen again. This endless cycle of recurring issues leads to predictable, yet entirely preventable, disruptions.

A reactive approach is like hitting the snooze button on a fire alarm. You're silencing the immediate warning without doing anything about the fire, which continues to grow in the background.

This way of working creates an environment where hazards are just waiting for the right conditions to cause a serious incident. The financial and operational fallout can be massive.

Counting the Hidden Costs

The real cost of a reactive stance goes far beyond the obvious. When an incident occurs, even a minor one, it kicks off a chain reaction of hidden expenses that drain resources and kill productivity.

Think about the real-world consequences:

- Lost Productivity: Work grinds to a halt in the affected area. Other team members stop what they're doing to help, watch, or just talk about it. Managers get pulled from their core duties to investigate and file reports.

- Operational Delays: The incident might damage a critical piece of equipment, stopping a production line. This can lead to missed deadlines, contract penalties, and a damaged reputation with your clients.

- Administrative Burden: The paperwork that comes with investigating an incident, managing a claim, and dealing with regulators is a huge drain on time and admin resources.

- Increased Insurance Premiums: A poor safety record with frequent claims will inevitably lead to higher premiums. That's a direct and ongoing financial hit.

The economic impact is huge. New Zealand’s workplace safety record shows the high price of falling behind other countries. In 2023 alone, workplace accidents cost the economy roughly NZD 4.9 billion in lost productivity, treatment, and compensation. Kiwis are nearly twice as likely to die in workplace accidents as their Australian counterparts, with an injury rate about 25% higher. You can discover more about these findings on worker safety.

Ultimately, seeing safety systems management as just another cost centre is a fundamental mistake. A proactive system is an investment in your operational stability and financial health. It prevents the major disruptions that a reactive approach simply accepts as part of doing business. It's the practical, business-savvy case for making your workplace consistently safe.

Using Technology to Support Your Safety System

Let's be honest, managing a safety system with binders, spreadsheets, and an endless paper trail is a recipe for failure. It's an outdated approach that can't keep up. Robust safety management software gives us practical tools to run a safety systems management plan consistently and effectively, especially in fast-paced industrial settings.

These tools don't replace your safety system; think of them as the engine that makes it run. Technology helps turn your documented procedures into everyday actions. It reduces the admin load, improves communication, and gives you a real-time view of what's happening on the ground. This means less time chasing paperwork and more time focused on managing actual risks.

Digital Forms and Real-Time Reporting

One of the quickest wins you'll see from technology is the shift to digital forms. Pre-start checks, site inspections, and hazard reports can all be done on a tablet or mobile phone, right there at the worksite. This simple change has a massive impact.

Instead of a clipboard with damp, illegible paper, a worker can use a device, tick off a checklist, snap a photo of a hazard, and hit 'submit'. The information is instant, accurate, and automatically logged. There’s no delay waiting for forms to get back to the office, and zero risk of them getting lost along the way.

This instant reporting loop is critical. A hazard identified on the morning shift at a manufacturing plant can be seen by the safety manager in the office moments later, allowing for a much faster response.

This digital approach builds a live, evolving picture of site safety. Managers can see that inspections are being done on schedule and can immediately flag any issues for action, which brings us to the next key function.

Centralized Platforms for Tracking Actions

A classic failure point in any safety system is the follow-through on corrective actions. A problem is found during an inspection, it’s noted down, and then the report gets filed away, forgotten until the same issue causes an incident. Sound familiar?

A centralized platform solves this by creating a single source of truth for every safety-related task. Here’s how it usually works:

- Action Creation: A hazard report or a failed inspection item automatically creates a corrective action task in the system.

- Assignment: The task gets assigned to a specific person (like a maintenance supervisor) with a clear due date.

- Tracking: The system tracks the task's status from "open" to "in progress" to "completed."

- Verification: Once the job is done, the person responsible can upload a photo as proof, and the action is officially closed out.

This creates clear accountability. Nothing gets lost in an email inbox or forgotten on a notepad. Managers get a dashboard view of all outstanding actions, who owns them, and how long they've been open. It makes it obvious which issues are being sorted and which ones have stalled.

The system makes sure that identifying a risk is only the first step and that follow-up is guaranteed. This level of tracking is a core benefit of modern safety systems management software. As technology evolves, we're also seeing new ways it can analyze this data; you can learn more by exploring how AI is revolutionising workplace safety.

Improving Consistency and Follow-Through

Ultimately, technology is a powerful driver of consistency. In high-pressure construction and manufacturing environments, it's easy for safety procedures to get pushed aside when schedules are tight. Digital systems help enforce the process every single time.

A worker can't submit a pre-start check without filling in all the required fields. A corrective action stays open and visible on a manager's dashboard until it’s officially closed. This builds a reliable workflow that makes sure the essential steps of your safety system are followed, day in and day out.

It's all about using tools to support your people and making the right way the easy way.

Got Questions About Your Safety Management System?

Even the best-laid plans run into real-world questions. When you’re trying to put a safety systems management framework into action, practical concerns always pop up. We hear a lot of the same queries from managers in construction and manufacturing, so here are some straight answers to help you make the right calls.

What’s the Real Cost of a Safety Management System?

This is usually the first question on everyone's mind, and the honest answer is: it depends. The price tag is tied directly to your company’s size, the specific risks of your industry, and how much you’ve already got in place. Your initial outlay might cover new safety gear, specialized training for your crew, or management software.

But here’s the thing, it's far better to think of this as an investment, not a cost. The fallout from a single serious incident, from lost work and damaged gear to hefty fines and soaring insurance premiums, almost always costs more than a solid safety system. The smartest move is to start with a baseline assessment to pinpoint your biggest risks, then budget to tackle the most critical stuff first.

How Do I Get My Crew to Actually Follow the Rules?

Getting your team on board comes down to two things: involvement and clarity. The single most effective way to get buy-in is to bring your workers into the process from day one, especially when you’re writing procedures for the tasks they do every day. They know the real-world risks better than anyone and have the best insights into what will actually work on the floor.

When workers help build the system, they take ownership of it. Their input makes the procedures practical, and their involvement turns them into champions for the change among their peers.

Make sure your training is hands-on and practical, not just death-by-PowerPoint. Crucially, leadership has to walk the talk. When your crew sees supervisors following every single safety rule without taking shortcuts, they’ll understand that’s the standard for everyone. You also need to make it simple for them to report hazards and give feedback without any fear of comeback.

We’re a Small Business. Do We Really Need a Formal System?

Yes, you absolutely do. A small business might not need the mountain of paperwork a huge corporation does, but the core principles of safety systems management are just as vital. You still need a reliable, structured way to spot hazards, control risks, and plan for emergencies, no matter how big your team is.

For a small outfit, a "formal" system could be as simple as:

- A well-organized binder with clear, simple procedures for your high-risk tasks.

- A set schedule for regular, documented safety meetings.

- Consistent use of inspection checklists for all your key equipment.

The goal isn't to create bureaucracy for the sake of it. It’s about having a systematic approach that makes sure safety is managed properly every day, not just when you get a spare moment. This is what stops incidents before they happen and builds a solid foundation for your business, whatever its size.

Ready to move beyond paper and spreadsheets? The Safety Space platform is designed to make your safety systems management practical and effective. It provides a single, easy-to-use place for everything from inspections and hazard reporting to tracking corrective actions, giving you real-time oversight of your entire operation. Book a free demo today to see how Safety Space can simplify your compliance and protect your team.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.