Global compliance certification is the formal proof that your business follows internationally recognised rules for quality, safety, or environmental impact. Think of it as a universal key that opens doors, showing customers and regulators that your operations meet a specific set of standards. This makes it a whole lot easier to win contracts and operate across different markets.

What Global Compliance Certification Really Means

At its heart, global compliance certification is all about creating a common language for business. It’s a way for a manufacturing company in Australia to prove its quality control is just as reliable as a competitor's in Germany, without having to explain every single internal process from scratch.

It’s not just about getting a certificate to hang on the wall; it’s about putting a structured system in place that delivers consistent, predictable results.

Imagine a construction firm pursuing an environmental management certification. This tells potential clients and government agencies that the company has formal, repeatable processes for managing waste, controlling pollution, and reducing its environmental footprint. It's not a vague promise. It's a verifiable system, checked and confirmed by an independent third party.

Building Trust Through Standards

That independent verification is what gives the certification its real muscle. It cuts through the noise and builds a solid foundation of trust.

When a large corporation is looking for a new supplier, they often make specific certifications a non-negotiable prerequisite. Why? Because it’s a shortcut. It immediately tells them the supplier has a proven system in place for managing the things that matter most.

A global compliance certification acts as a passport for your products and services. It confirms you meet the entry requirements for new markets, supply chains, and high-value contracts without needing to prove your credibility from the ground up every single time.

This trust is absolutely crucial for any business looking to grow. Without it, you’re stuck in a loop, constantly trying to convince potential partners that your internal processes are good enough. Certification does that heavy lifting for you.

Practical Applications in Your Industry

So, what does this actually look like day-to-day? It’s less about abstract rules and much more about practical, repeatable actions that make your business run better. For businesses in demanding sectors like construction and manufacturing, this translates directly to operational stability.

Here’s what it means on the ground:

- Consistent Product Quality: A certified factory has documented procedures for every stage of production. From inspecting raw materials to final product testing, everything is planned. This means fewer defects and confidence that every item leaving the line meets the exact same standard.

- Structured Environmental Management: A construction company with an environmental certification has clear, pre-defined steps for handling chemical spills, managing site runoff, and sorting waste for recycling. These things aren't left to chance; they're part of a planned and audited process.

- Clear Operational Guidelines: Getting certified forces you to document everything clearly. Your team knows exactly what steps to follow, how to report issues, and who is responsible for what. The result is fewer mistakes and better coordination across the board.

Ultimately, achieving a global compliance certification isn't just a box-ticking exercise; it's a smart business decision. It provides a solid framework to run your operations more effectively and signals to the world that your company is reliable, responsible, and ready for business.

Key International Standards for Your Business

Jumping into global compliance means getting your head around a few key international standards. While there's a whole alphabet soup of certifications out there, a handful managed by the International Organization for Standardization (ISO) really matter for businesses in construction and manufacturing.

These aren't just bureaucratic badges to collect. They're practical frameworks that give you a proven blueprint for running specific parts of your business, from quality control to worker safety.

The first step is figuring out which standards apply to you. Think of them as different tools in a toolbox. You wouldn't use a sledgehammer to fix a leaky tap, and you wouldn't use a quality management standard to manage your environmental footprint. Each ISO standard has a specific job, helping you build a more robust, reliable, and respected operation.

Let's break down the three you'll come across most often.

ISO 9001: Quality Management

ISO 9001 is probably the most famous of the bunch, and it’s all about quality management. For a manufacturer, this is the system that makes sure every widget coming off your production line is consistent and lives up to what your customers expect. Simple as that.

It doesn’t tell you what makes a good product. Instead, it gives you a framework to define your own quality goals and then build repeatable processes to hit those targets, time and time again. This covers everything from how you handle an initial customer order to how you vet your suppliers and manage your production line.

For a construction firm, ISO 9001 applies to your project management systems. It helps you make sure that every stage of a build, from the first sketch to the final handover, follows a documented, consistent, and quality-driven procedure. This is how you cut down on errors, avoid costly rework, and keep clients happy.

ISO 14001: Environmental Management

Next up is ISO 14001, which zeroes in on environmental management. This standard provides a formal system for measuring and improving your company's environmental impact. In sectors like construction and manufacturing, where your work can really affect the world around you, this certification is becoming a must-have.

Getting ISO 14001 certified shows you have a plan. It proves you've identified your environmental risks, things like chemical storage, waste disposal, or energy use, and have put solid controls in place to manage them.

For a construction site, this might mean having clear processes for controlling soil erosion and stopping pollutants from getting into local waterways. For a factory, it could be a system to reduce water consumption or manage air emissions. It’s a practical framework for being a responsible operator.

More and more, this standard is a non-negotiable for government tenders and big corporate contracts, where a clean environmental record is a major deciding factor.

ISO 45001: Occupational Health and Safety

Finally, we have ISO 45001, the global benchmark for occupational health and safety (OH&S) management systems, often supported by specialized OHS software. Its core mission is simple: help organisations prevent work-related injuries and illness. The standard gives you a structured way to spot hazards, assess risks, and put controls in place to make the workplace safer for everyone.

In high-risk industries, this isn't just a nice-to-have; it's essential. It pushes a business to stop reacting to incidents and start proactively managing health and safety. The framework helps you build systems for everything from staff training and equipment maintenance to emergency plans and incident investigations.

Let's face it, managing all this can be complex. That's where dedicated tools can make a world of difference. You can learn more about managing these processes with specialised health and safety management software.

A Comparison of Key Global Compliance Standards

To make things clearer, here’s a quick look at how these three major international standards stack up, their core focus, and where they're most often applied.

| Standard | Main Focus | Typical Industries |

|---|---|---|

| ISO 9001 | Quality Management & Consistency | Manufacturing, Engineering, Construction, Technology |

| ISO 14001 | Environmental Impact & Sustainability | Construction, Manufacturing, Mining, Waste Management |

| ISO 45001 | Occupational Health & Safety (OH&S) | Construction, Manufacturing, Logistics, Energy |

Ultimately, choosing the right standard, or combination of them, boils down to your business goals, what your industry demands, and what your customers expect. Each one provides a clear path to a more organised and dependable operation, making them a cornerstone of any serious global compliance strategy.

The Tangible Benefits of Getting Certified

Chasing a global compliance certification isn't just about ticking boxes for the regulators. It's a strategic move that delivers real, measurable results for your business, especially when it comes to winning new work and sharpening up how you operate.

For many large corporations and government bodies, certification isn't a "nice-to-have," it's a non-negotiable. Without it, you’re not even in the running. This is where you see the true value kick in: it opens doors that would otherwise be firmly shut.

Picture an Australian manufacturer wanting to get into a major European supply chain. The very first question they'll face is about their quality management system. An ISO 9001 certification answers that question instantly, giving them the verified proof big partners need before they’ll even start talking contracts.

Winning Better Contracts

Having a global compliance certification simply makes your business a more attractive partner. It’s a clear signal to potential clients that you’re organised, reliable, and take your operational duties seriously. This is especially true for the big, high-stakes projects.

Take a construction firm in Australia bidding for a major government infrastructure project. Those tenders will often explicitly require certifications like ISO 14001 for environmental management and ISO 45001 for health and safety.

A certification moves your business from the "maybe" pile to the "serious contender" list. It shows you already have the systems in place to handle complex project requirements, reducing the perceived risk for the client and giving you a major competitive advantage.

This means you’re not just qualifying for more work; you're qualifying for better work. The kind that comes from larger, more established clients who value structured processes and documented accountability.

Reducing Operational Risk and Costs

Beyond winning new business, certification has a direct impact on your day-to-day operations. It forces you to establish clear, repeatable processes for critical tasks, which naturally cuts down on costly mistakes and potential legal dramas.

When your team follows a documented procedure for handling materials or managing site waste, there's just less room for error. This consistency leads to fewer defects, less rework, and a lower chance of incidents that could result in hefty fines or legal action.

Here’s how this plays out on the ground:

- Fewer Production Errors: A certified quality management system helps a factory spot issues early, leading to less waste and a higher-quality final product.

- Lower Chance of Fines: By implementing a formal environmental management system, a business can stay on top of its compliance obligations, reducing the risk of expensive penalties for breaches.

- Improved Efficiency: Standardised processes mean everyone knows their role and the right way to do things, which leads to better workflow and less wasted time.

This structured approach helps you catch problems before they become big, expensive headaches. It's about building a solid operational foundation, something fundamental to any well-run business. Many companies find that having a central place to manage these processes, like a good safety management system, brings all these moving parts together.

Building a Stronger Reputation

Finally, a global compliance certification is a massive boost to your company's reputation. It’s a public statement that your business is committed to international best practices, whether that's in quality, safety, or environmental care.

This builds trust not only with clients but also with suppliers, employees, and the wider community. A solid reputation can lead to better supplier relationships, attract top-tier talent, and make your company more resilient in the long run. It proves you're a professional outfit that invests in doing things the right way, and that’s a message that resonates in any industry.

Your Step-by-Step Path to Certification

Embarking on the journey to a global compliance certification can feel like a mammoth task. But when you break it down into clear, logical steps, it becomes far more manageable. Don't think of it as one massive project; see it as a sequence of practical tasks, with each one building on the last.

This roadmap will guide you through the whole process, from the initial decision right through to long-term maintenance. The goal here is to make the process feel straightforward, giving any business a clear plan to navigate certification and build a solid operational framework.

Step 1: Choose the Right Standard

Before you do anything else, you need to pick the standard that actually fits your business. As we've covered, standards like ISO 9001, ISO 14001, and ISO 45001 each have a different focus. The right choice hinges on your industry, what your customers expect, and your own business goals.

For instance, a manufacturing firm that wants to crack a new market where product consistency is king should start with ISO 9001. On the other hand, a construction company bidding on government projects with strict environmental clauses should prioritise ISO 14001.

Step 2: Perform a Gap Analysis

Once you’ve settled on a standard, the next step is to figure out where you currently stand. A gap analysis is just a thorough review of your existing processes compared against the requirements of the standard you’ve chosen. Think of it as a "you are here" map for your compliance journey.

This analysis will shine a light on what you're already doing well and, more importantly, where the gaps are.

- What it finds: Missing documents, undefined processes, and any areas where your operations fall short of the standard.

- Why it's crucial: It gives you a specific, actionable checklist of what needs fixing. Without it, you're just guessing.

You can run this internally if you have the expertise, or bring in an external consultant for a fresh, objective view. The outcome should be a clear report detailing every area that needs attention before you can move forward.

Step 3: Develop and Document Your Procedures

With your gap analysis in hand, it’s time to start filling those gaps. This means creating new procedures and, critically, documenting everything. If a process isn't written down, as far as an auditor is concerned, it doesn't exist.

This is where you translate the standard's high-level requirements into practical, day-to-day actions for your team.

For a factory, this could mean creating a formal document that outlines the exact steps for inspecting incoming raw materials. For a construction site, it might be a written procedure for safely storing hazardous chemicals.

Documentation doesn't need to be complicated. In fact, it shouldn't be. Keep it clear, concise, and easy for your team to follow. This is the core of your new management system, so take the time to get it right.

Step 4: Train Your Team and Implement

A documented system is useless if your team doesn't know how to use it. This next phase is all about training and implementation. Everyone, from the factory floor to the management office, needs to understand the new procedures and their role in making them stick.

This stage is vital for making the system a real, living part of your business. It's not about a one-off training session; it requires ongoing communication and support to make sure the new processes are being followed correctly and consistently.

Step 5: Prepare for the External Audit

After your new system has been up and running for a few months, it's time to prepare for the main event: the external audit. This is where an independent auditor from a certification body visits your business to verify that your system meets all the requirements of the standard.

To get ready, you should first conduct an internal audit. Think of it as a dress rehearsal. You check your own system to find and fix any last-minute issues before the official auditor arrives. It's your final chance to make sure all your paperwork is in order and that your team is following the procedures.

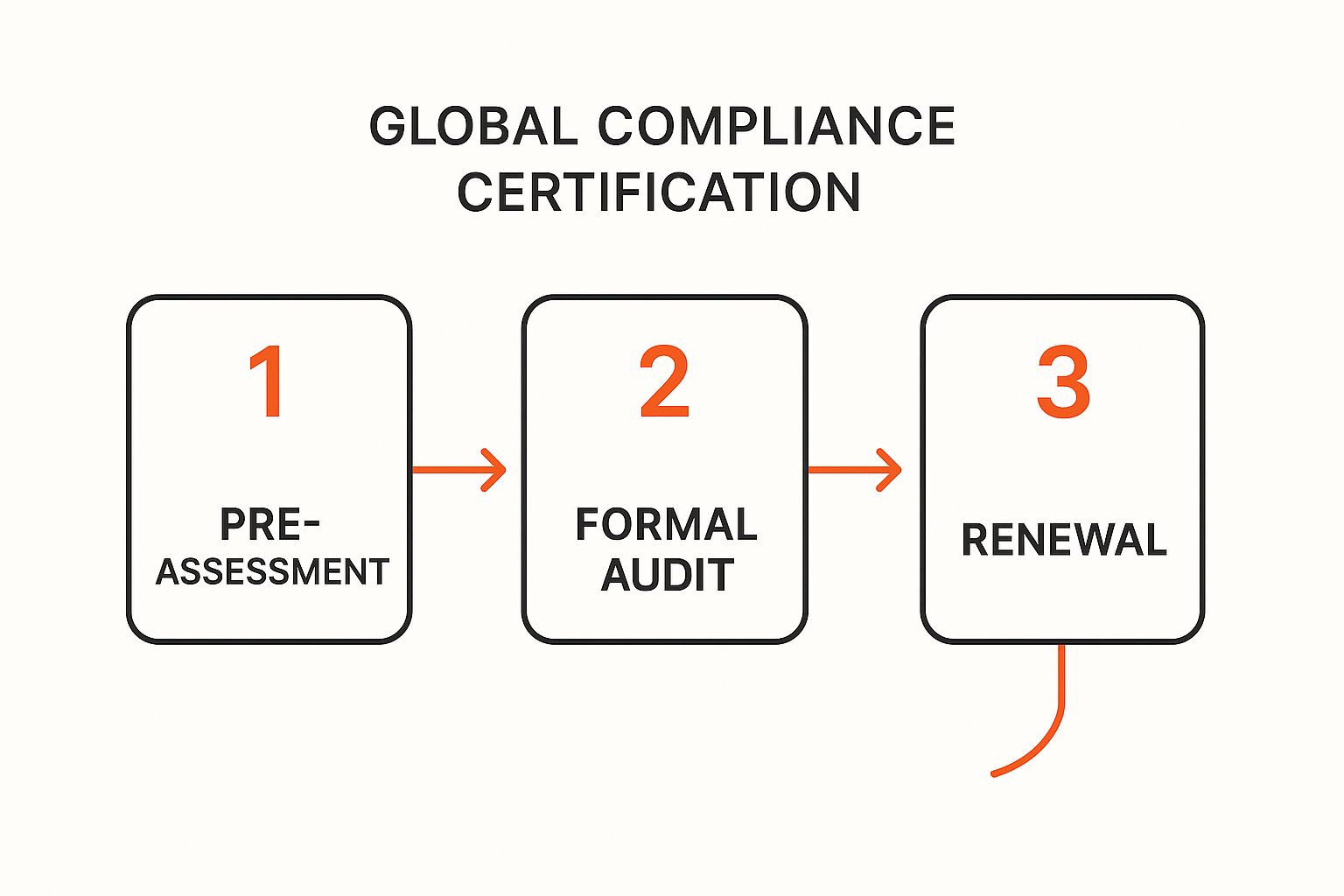

This infographic shows the simplified, three-stage cycle of achieving and maintaining your certification.

This visual highlights that certification isn't a one-and-done deal. It's a continuous process of assessment, verification, and renewal to make sure standards are consistently met.

Step 6: Maintain Your Certification

Congratulations, you're certified! But the work doesn't stop here. Your global compliance certification isn't a lifetime award; it requires ongoing effort to maintain.

Most certifications are valid for three years and require annual surveillance audits to make sure you're still playing by the rules. This means you need to keep your system running, conduct regular internal audits, and continually look for ways to improve. Maintaining your certification shows a long-term commitment to quality and is the key to reaping the ongoing benefits.

Common Challenges in the Certification Process

https://www.youtube.com/embed/yumTif3Yw4Q

Getting a global compliance certification is a massive win, but let's be honest, it’s not a walk in the park. Pretending the process is easy is the fastest way to set your business up for failure. A clear-eyed view of the hurdles you’re likely to face is the first real step toward getting over them.

Too many companies underestimate what’s involved and end up bogged down by surprise costs, stretched resources, and a total loss of momentum. If you can spot these common roadblocks upfront, you can build a solid plan to navigate the process without derailing your day-to-day operations.

The Initial Cost and Time Commitment

The first thing most businesses notice is the direct hit to the budget. You’ve got fees for the certification body, the cost of any consultants you bring in, and maybe even investments in new equipment or software. It all adds up, and quickly.

But the invoices are only half the story. The time your team has to sink into this is a huge, and often hidden, expense. Your key people will spend hours documenting processes, sitting through training sessions, and taking part in audits. That’s time they aren’t spending on their actual jobs, and if you don’t plan for it, productivity will take a nosedive.

A classic mistake is cobbling together a budget that only covers the direct expenses while ignoring the cost of your team's time. Without a proper financial plan, the whole project can stall or put a serious strain on your business.

Keeping Up with Changing Rules

Global compliance isn’t a one-and-done task. The standards themselves get updated, and the local regulations that impact your compliance can shift even more often. For example, an environmental standard might get an update with stricter emissions targets, forcing you to overhaul your internal processes.

This means you absolutely need a system to stay on top of these changes and adapt. If you don’t, you could easily put your hard-earned certification at risk when the next surveillance audit rolls around. A lot of businesses stumble here because they never assign anyone the clear responsibility of monitoring regulatory updates, leaving them exposed when the goalposts move.

The real work of a global compliance certification isn't just achieving it; it's maintaining it day after day. This requires a proactive system for tracking changes, updating documents, and making sure your team stays aligned with the latest requirements.

This ongoing maintenance is exactly where things tend to fall apart. A certificate you earned in 2023 might be worthless if your processes haven’t kept pace with new rules that came out in 2025.

Getting Full Team Support

You can have the most beautifully documented system on the planet, but if your team isn’t on board, it’s useless. Getting genuine buy-in from everyone, from the senior leadership team right down to the people on the factory floor, is one of the toughest parts of the whole process.

If managers just see certification as more admin work, they won't make it a priority. If employees think the new procedures are just pointless extra steps, they’ll find workarounds. This kind of resistance can completely sabotage the effort and make it impossible to pass an audit.

The solution comes down to clear communication. Everyone needs to understand why this certification matters to the business and what their specific role is in making it a reality. Without that shared mission, you’ll be fighting an uphill battle the entire way.

Solving Common Certification Hurdles

The good news is that none of these challenges are a surprise. Because they’re predictable, they’re also manageable. Having a solid strategy in place before you start makes all the difference. Regular internal checks are a massive part of this, and it’s worth learning about the importance of regular safety audits for your business to keep your systems sharp.

Knowing what you're up against is half the battle. Here’s a quick look at these common issues and some practical ways to tackle them.

| Challenge | Practical Solution |

|---|---|

| High Initial Costs | Develop a detailed budget that includes audit fees, consulting costs, and an estimate for internal staff time. Seek quotes from multiple certification bodies. |

| Keeping Documents Organised | Use a central digital platform to store, update, and share all compliance documentation. This avoids version control issues and makes information accessible for audits. |

| Lack of Team Buy-In | Involve team members from all levels in developing the new procedures. Clearly communicate the business benefits, such as winning new contracts, to show the value of their effort. |

| Maintaining Compliance | Assign a specific person or team to be responsible for tracking regulatory updates. Schedule regular internal audits to check that processes are still being followed correctly. |

By anticipating these hurdles, you can turn a potentially chaotic process into a structured and successful project.

The Future of Global Compliance

If you think global compliance certification is a static, tick-the-box exercise, you might be in for a shock. The entire field is moving fast, becoming more tangled up with technology and facing much sharper teeth from regulators. This isn't a one-time project anymore; it's a living, breathing part of your business. If you want to stay ahead, you need to see where it's all going before it becomes a problem you can't ignore.

Technology, for one, is changing everything. We’re seeing a massive shift away from dusty filing cabinets and clunky spreadsheets. Modern software platforms are now the command centre for managing compliance docs, getting automatic alerts on regulatory changes, and even monitoring processes in real time. It just makes the whole business of staying compliant far more manageable, especially when you're juggling multiple sites or teams.

Stricter Enforcement and Higher Stakes

At the same time, the consequences of getting it wrong are getting more severe. Regulators are cracking down, and the penalties for non-compliance aren't just a slap on the wrist anymore, they're the kind of fines that can seriously hurt a business.

Just look at what’s happening in Australia. We're seeing major reforms across the board. A mandatory administrative regime for merger notifications is kicking in on 1 January 2026. On top of that, new rules like the Scams Prevention Framework Bill carry potential fines of up to AUD 50 million for companies that don't meet their legal duties. It’s a clear signal from regulators, and you can get more detail on these risks from the legal experts at Gilbert + Tobin.

And this isn't just an Aussie trend; it’s happening everywhere. It hammers home the point that getting your global compliance certification is just the start line. The real marathon is keeping it.

The Push for Greater Transparency

The other big shift is the demand for transparency. It's no longer enough to just be compliant; you have to show you are. Companies are increasingly expected to report publicly on what they're doing, particularly in high-risk industries like construction and manufacturing. This isn't about ticking boxes for the government. It's about earning trust with your customers, investors, and the community.

This shift means your compliance systems are no longer just an internal matter. They are becoming a public statement about your company's commitment to quality, safety, and ethical operations, directly impacting your brand reputation and ability to win business.

Looking at it this way, it’s obvious that managing compliance properly is a core part of any smart business strategy. It needs constant attention, the right mindset, and the right tools to keep everything organised and on track.

Juggling all these moving parts, documentation, audits, and constant regulatory updates, can feel like a full-time job in itself. Safety Space brings your entire health and safety system into one simple platform, helping you stay compliant so you can get back to focusing on your business. See how Safety Space can work for you.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.