A WHS Management Plan is your company's playbook for keeping people safe, but it's much more than a document that sits on a shelf. Think of it as a living guide that outlines the practical steps you'll take to find, assess, and control workplace risks, often supported by modern workplace safety software, ensuring you meet your legal duties under WHS law.

What a WHS Management Plan Actually Includes

Let's cut through the jargon. A WHS management plan is the foundation for all your safety activities. It makes sure everyone, from the director right down to a new hire, knows exactly what their role is in keeping the workplace safe. It is not about creating endless paperwork; it is about building a clear, functional system that actually works in the real world.

Regulators want to see a structured approach that is specific to your business and your unique risks. This is where generic, off-the-shelf templates fall short. They cannot possibly account for the specifics of your site, your people, or your particular high-risk tasks.

The Core Components of Your Plan

To be effective, your plan needs to be built on several key pillars. These are the non-negotiable elements that give it structure and purpose. Think of them as the essential chapters in your safety playbook.

Some of the key things you absolutely must include are:

A clear, concise WHS policy that shows your company's commitment to safety.

Clearly defined roles and responsibilities. Who is accountable for what? Spell it out for managers, supervisors, and workers so there is no confusion.

Proper risk management procedures that detail how you find hazards, assess the level of risk, and put effective controls in place.

Emergency plans and procedures for when things go wrong. This needs to cover everything from first aid response to a full site evacuation.

Training and induction processes, including how you will make sure workers are competent to do their jobs safely and how you'll keep records of all training.

A common mistake I see all the time is a business creating a plan and then never looking at it again. Your WHS management plan should be a working document. It needs to be referenced regularly: during project planning, in team meetings, and especially after any incident.

While these components form the basic structure, it is vital to see them as interconnected parts of a whole system, not just a checklist. You can explore the key elements of a health and safety management system to get a deeper understanding of how these pieces fit together.

To make it even clearer, here's a simple breakdown of what each essential part of the plan covers.

Core Components of an Effective WHS Management Plan

This table outlines the essential elements your plan must include to be complete and compliant with Australian standards.

Component | What It Covers |

|---|---|

WHS Policy | A formal statement of commitment from senior management to provide a safe and healthy workplace. |

Roles & Responsibilities | Who is accountable for specific safety tasks, from the PCBU down to individual workers and contractors. |

Risk Management | The process for identifying hazards, assessing risks, and implementing control measures using the hierarchy of control. |

Emergency Preparedness | Detailed procedures for responding to incidents, accidents, and emergencies, including first aid and evacuation protocols. |

Consultation & Communication | How you will consult with workers and other stakeholders on WHS matters. |

Training & Competency | Procedures for induction, task-specific training, and maintaining training records to make sure workers are competent. |

Incident Reporting | A clear process for reporting all incidents and near misses, including investigation and corrective action procedures. |

Plan Review | A schedule and process for regularly reviewing and updating the WHS plan to make sure it remains current and effective. |

Having these components in place gives you a solid framework that does not just tick boxes, but actively drives a safer work environment for everyone involved.

How to Find and Assess Your Workplace Risks

Before you can think about controlling workplace risks, you have to get out there and find them. This is not about ticking boxes on a generic checklist; it's the most critical fieldwork you'll do for your WHS management plan, requiring you to look at your site with fresh eyes.

The numbers really drive home why this matters. Over the last decade, Australia has seen more than 1,850 work-related traumatic fatalities and over 1.14 million serious workers' compensation claims. These are not just statistics; they're real people, and many of these incidents could have been prevented with a solid WHS plan. You can dig into the latest Safe Work Australia WHS statistics to get the full national picture.

A solid risk identification process is your first and best line of defence. It is about being methodical and questioning the things that have become "normal" but are actually brewing trouble.

Practical Ways to Uncover Hazards

Finding risks is not a one-off job you can do from your desk. It is an ongoing effort that needs a few different approaches to build a complete picture of what is really happening on the ground.

A great place to start is with regular workplace inspections. This means getting your boots on the ground, walking through every work area, and watching how tasks are actually done. Talk to the people doing the work. Don't just scan for the obvious stuff like unguarded machines or trip hazards. Listen for complaints about workflow, fatigue, or stress.

Just as important is reviewing past incident reports. Your own records of accidents, injuries, and especially near misses are a goldmine. They point directly to the weak spots in your current systems that your new WHS management plan absolutely must address.

Your team is your best asset for spotting hazards. The people operating the machinery or doing the manual handling every single day know the shortcuts, the frustrations, and the "unwritten" ways of doing things. A simple question like, "What's the most difficult or dangerous part of your job?" can uncover risks you'd never spot from an office.

Looking Beyond the Obvious Physical Risks

While physical hazards are usually the easiest to see, psychosocial hazards are just as critical and are getting a lot more attention from regulators. These are the aspects of work design and management that can cause psychological harm.

Some of the most common psychosocial hazards to watch for include:

High Workloads: Are deadlines constantly unrealistic? This can lead to overwhelming pressure and burnout.

Low Job Control: Do your workers have very little say in how they carry out their tasks?

Workplace Conflict: Is there ongoing tension, bullying, or harassment that is not being addressed?

Poorly Managed Change: Are big organisational changes rolled out without clear communication, causing uncertainty and stress?

Identifying these often requires a more subtle approach, like confidential surveys or structured one-on-one chats with your team.

From Identification to Assessment

Once you have a list of hazards, the next move is to assess the risk each one poses. This is all about prioritisation: figuring out which problems need your immediate attention.

A straightforward way to do this is to look at two key factors for every hazard you have found:

Likelihood: How likely is it that something could go wrong because of this hazard?

Consequence: If it does go wrong, how bad would the outcome be?

By combining these two factors, you can sort your risks into categories (e.g., high, medium, low) using a risk register. This register becomes a core part of your WHS management plan, giving you a clear, actionable list of priorities to work through.

Putting Practical Control Measures in Place

Spotting risks is only half the battle. A risk you have identified but have not planned to control is simply a disaster waiting to happen. This is where your WHS management plan shifts from just assessing things to taking real, concrete action with practical and sustainable control measures.

The whole point is to land on the most effective and reliable solution you can. This is where the hierarchy of controls stops being some academic theory and becomes your go-to decision-making tool. It forces you to think from the strongest controls down to the weakest, so you do not just default to the easiest, quickest fix.

The best control measure is always the one that eliminates the hazard completely. If you can't get rid of it, you work your way down the hierarchy. Relying on personal protective equipment (PPE) should always be your last resort, never your starting point.

From Theory to On-site Action

Applying this hierarchy in the real world is what gives your WHS management plan its teeth. It pushes you and your team to find better, more permanent solutions instead of just slapping a band-aid on the problem.

Let's see how this plays out in different workplaces:

On a Construction Site: Instead of just telling everyone to wear a safety harness (PPE), a far better control is installing temporary guardrails around open edges. That is an engineering control, and it protects everyone without relying on each worker to do the right thing every single time.

On a Manufacturing Floor: Rather than only training workers on safe manual lifting techniques (an administrative control), the superior solution is to bring in mechanical lifting aids like hoists or conveyor belts. This is another engineering control that removes the manual handling risk.

In an Office Environment: To tackle fatigue from unrealistic workloads (a psychosocial hazard), you could redesign work processes or adjust deadlines (administrative controls) instead of just pointing people to a wellness app.

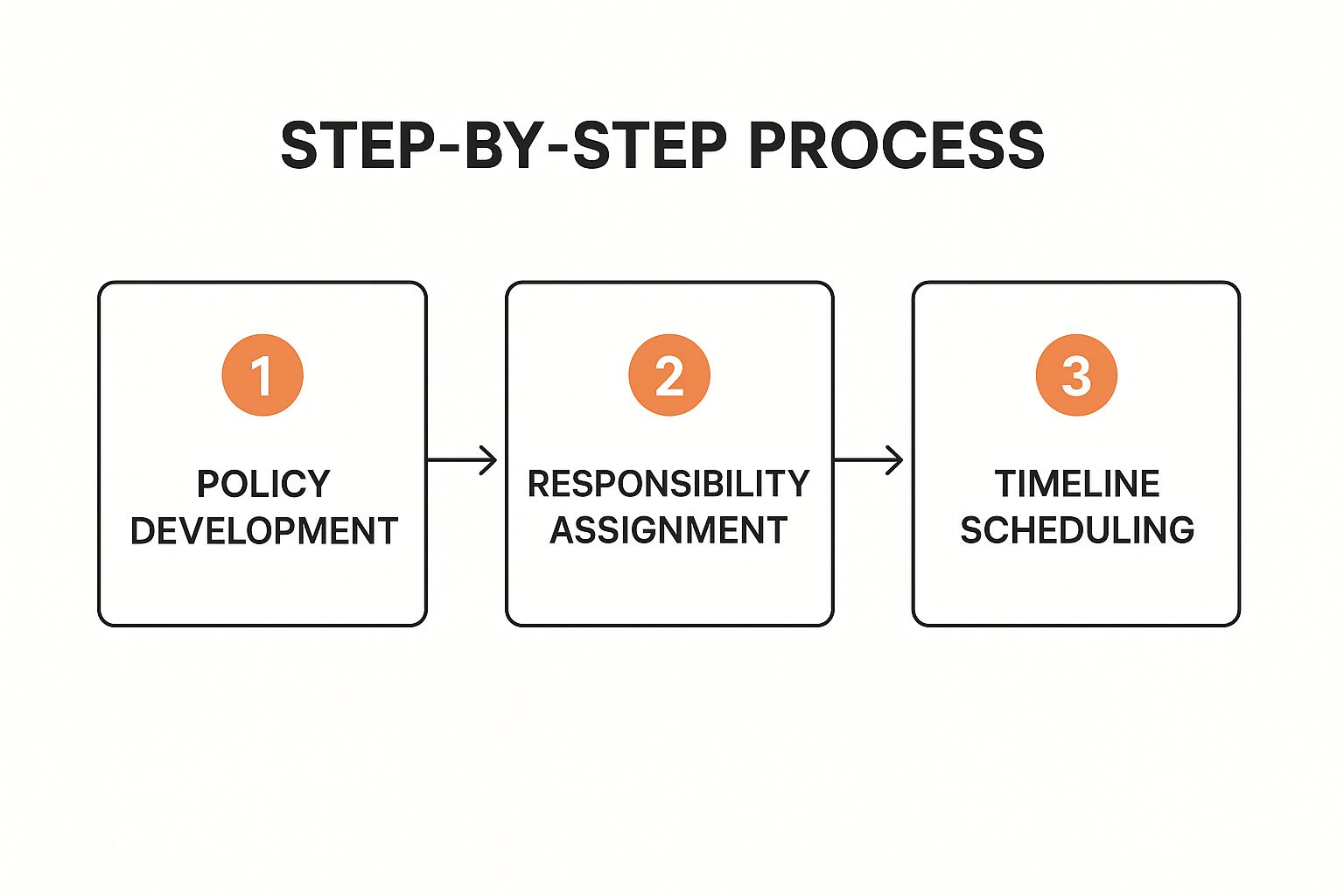

This whole process: developing policies, assigning clear responsibilities, and setting firm timelines: is what makes a plan truly functional.

This visual gives you a good sense of the logical flow: how you turn a great control idea into a required action that gets done across your organisation.

High-Stakes Industries Need Stronger Controls

The need for solid, enforceable controls is especially critical in high-risk sectors. Take the Australian construction industry, for example. It remains a major focus for regulators because of its stubbornly high rates of injury and death, second only to transport and warehousing.

During one recent compliance blitz, 213 construction site audits resulted in a staggering 674 statutory notices. This included 195 prohibition notices that shut down unsafe work on the spot. You can read more on the construction industry compliance focus and see just how serious this is.

This level of scrutiny makes it crystal clear: your WHS management plan cannot be just a document that gathers dust. Every single control measure needs to be detailed, assigned to a person, and tracked. Your plan must spell out:

What the control measure actually is.

Who is responsible for implementing it.

When it absolutely must be completed.

This kind of detail builds accountability and turns your plan from a piece of paper into a powerful management tool that actively protects your people.

Right, you have put in the hard work and built a solid WHS management plan. But here is the rub: if it just gathers dust in a folder on the manager's shelf, it is completely useless.

A plan only comes to life when it is part of your daily operations. That means you need a proper launch and, just as importantly, clear and ongoing communication. This is not just about ticking a box or sending out a single company-wide email. It is about embedding safety thinking into every role, making the plan accessible, relevant, and understood by everyone.

A successful rollout turns your WHS plan into a living, breathing tool that people actually use.

Choosing the Right Way to Communicate

People absorb information in different ways, especially when you have teams doing vastly different jobs. A one-size-fits-all communication blast is almost guaranteed to fail. You have got to be smarter and tailor your approach to reach different teams where they are.

Think about which channels make the most sense for your people:

Toolbox Talks: For your crews on the factory floor or a construction site, you cannot beat short, sharp toolbox talks. These are perfect for focusing on a specific risk relevant to their immediate tasks, like the safe use of a new bit of machinery or a change in a high-risk procedure.

Team Meetings: Office-based staff will likely tune out of a toolbox talk, but they will pay attention in their regular team meetings. This is the ideal time to cover parts of the WHS plan that directly affect their world, like new emergency evacuation routes or ergonomic standards for their workstations.

Email & Intranet Updates: For general announcements, updates, or making the full plan available, your company intranet and email are still great tools. They create a paper trail and give everyone a central place to find the official documents when they need them.

A critical mistake I see all the time is treating WHS training as a one-off, tick-a-box induction exercise. Real training is about making sure people get it. Instead of just presenting information, wrap up your sessions with practical questions. Ask things like, "Okay, so if this specific alarm sounds, what are the first two things you do?" The goal isn't just awareness; it's building the confidence to act correctly without hesitation.

The Power of Consultation During the Rollout

Launching your WHS plan is not a one-way street where management talks at the team. It absolutely has to be a conversation where you talk with them.

Consultation at this stage is your secret weapon. It demonstrates that you actually listened to their feedback during the risk assessment phase and that their input has shaped the final plan. This is how you build a sense of shared ownership.

When you present the plan, make a point to highlight the changes that came directly from worker feedback. Saying something like, "Remember those concerns you raised about the slippery walkway? That is why we have installed this new guardrail," immediately makes the process feel like a genuine two-way street.

And this dialogue cannot just stop after the launch party. Here is how to keep the conversation going:

Establish Dead-Simple Feedback Channels: Make it incredibly easy for anyone to ask a question or report a hazard. This could be a dedicated email address, a physical suggestion box in the break room, or a genuine open-door policy with supervisors and managers. The easier it is, the more you will get.

Lean on Your Safety Champions: Look for those influential, respected people within your teams who can act as safety champions. These are not just management mouthpieces; they are credible peers who can translate the messages and, more importantly, bring back honest, unfiltered feedback from their colleagues.

Make Leadership Visible: Nothing reinforces the importance of safety more than seeing senior leaders actively involved. When a director joins a safety walk-through or asks questions in a team meeting, it sends a powerful signal. It shows everyone that WHS is a core business priority, not just some compliance task you have handed off to the safety team.

Keeping Your Plan Relevant with Regular Reviews

Look, a WHS management plan is not a trophy you write once and then stick on the shelf to gather dust. Workplaces are living, breathing things. People come and go, equipment gets upgraded, and processes get tweaked. A plan that was watertight six months ago could be full of holes today.

This is exactly why regular reviews are not just a "nice-to-have" or best practice: they are a legal requirement. Frankly, an out-of-date plan is almost as dangerous as having no plan at all. It creates a false sense of security, leaving your team exposed to uncontrolled hazards and your business exposed to serious non-compliance penalties.

Setting a Regular Review Cycle

Treat your plan's review cycle like a scheduled service for your most critical piece of machinery. You would not skip that, would you? As an absolute minimum, you need to schedule a comprehensive review at least once every 12 months. This annual deep dive is your formal chance to go through the whole document and make sure it still reflects how you actually work.

But let's be realistic: a lot can happen in a year. Waiting for that annual date to roll around is often too long. Certain events should trigger an immediate review of your plan, no matter when you last looked at it.

Key triggers for an unscheduled review include:

After any significant incident or a near miss. This is a massive red flag that a control measure failed or a hazard was completely missed.

When new machinery or equipment is introduced. New gear brings new risks, new procedures, and new training needs your plan must address.

If there are changes to work processes or the work environment. Reconfiguring a workshop layout or changing production targets can introduce entirely new hazards.

Following consultation with your workers. If your team on the ground raises concerns or has ideas for improvement, that feedback needs to be formally reviewed and acted on.

When WHS legislation or codes of practice change. The law is not static. You have to adapt your plan to meet new legal goalposts.

A common mistake I see is businesses only reviewing their plan after a serious injury. A near miss is a gift. It's a free lesson on what could have gone terribly wrong, giving you the perfect opportunity to strengthen your plan before someone actually gets hurt.

Gathering Feedback and Measuring Performance

A review is so much more than just reading a document. It is about digging up real-world data to see if the plan is actually working. You need evidence from the ground, not just words on paper.

Your own incident data is one of the most powerful tools you have. Start looking for trends. Are you seeing the same minor hand injuries in one area over and over? That is a clear sign the controls listed in your plan for that task simply are not effective.

Regular site audits are also non-negotiable for checking compliance and effectiveness. These audits give you a real-time snapshot of how well the rules in your plan are being followed day-to-day. You can learn more about the importance of regular safety audits for your business in our detailed guide.

The Australian regulatory landscape is also shifting, with a much bigger focus now on both physical and psychological health. New WHS laws are bringing tougher penalties and a new emphasis on managing psychosocial hazards like workplace bullying or excessive workloads. Staying current means staying on top of these changes.

Finally, and this is crucial, every single review and change must be documented. This creates a clear historical record, showing exactly when your WHS plan was updated and why. This paper trail is your proof of due diligence for regulators and demonstrates you have a living, breathing system for managing safety.

Your Top WHS Management Plan Questions, Answered

Even with a solid grasp of what a WHS management plan should contain, practical questions always pop up. I get these all the time from businesses on the ground, so let's walk through some of the most common ones.

How Often Do I Need to Review My WHS Management Plan?

Legally, you have specific triggers that require you to review your WHS management plan. This includes things like after a workplace incident, when a new hazard rears its head, or if your team consultation flags a problem with the current system.

But relying only on those triggers is a reactive approach. Best practice, and what I always recommend, is to schedule a full, formal review at least once a year.

Think of it as a health check for your entire safety system. This annual check-up makes sure your plan has not gone stale and still aligns with your business operations, team changes, and any updates to WHS laws, often facilitated by comprehensive WHS software.

What's the Difference Between a WHS Plan and a SWMS?

This is a huge point of confusion, but the distinction is actually pretty simple once you get it.

Your WHS management plan is the big-picture document. It is your organisation's overarching strategy, outlining the entire system you use to manage health and safety across the board. It covers everything from leadership commitment to incident reporting.

A Safe Work Method Statement (SWMS), on the other hand, is laser-focused. It's a specific document legally required for 'high-risk construction work'. It breaks down a single task step-by-step, identifies the risks at each stage, and lists the exact control measures you will use.

A simple way to think about it: The WHS plan is the 'what we do for safety overall,' while the SWMS is the 'how we do this one specific high-risk task safely.'

Do Small Businesses Really Need a WHS Management Plan?

Yes, absolutely. Every single business in Australia, regardless of size, has a primary duty of care to protect its workers. There is no "small business" exemption when it comes to safety.

Now, the complexity of your WHS plan can definitely scale with your business. A small retail shop or a five-person office will not need the same beast of a document as a major manufacturing plant.

But you still need a formal, written system. It has to cover the essentials: how you find hazards, assess risks, control them, and plan for emergencies. Regulators expect every business, big or small, to have a structured approach. If you are not sure where your gaps are, running a health and safety self-assessment is a fantastic place to start.

Who Is Responsible for Creating the WHS Plan?

Ultimately, the legal buck stops with the Person Conducting a Business or Undertaking (PCBU): that is the company or employer.

But here is the crucial part: creating the plan should never be a solo mission cooked up behind a closed door. The most effective plans, the ones that actually work in the real world, are built through collaboration.

It is absolutely vital to consult with your workers, supervisors, and any health and safety reps. Their firsthand knowledge of daily tasks, unofficial shortcuts, and on-the-ground risks is pure gold. This input is what makes a plan practical and effective, not just a document that ticks a compliance box. While a safety manager might drive the process, buy-in from every level is the secret sauce.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free Demo