If you're running a business in Western Australia, the main piece of safety legislation you need to know is the Work Health and Safety Act 2020 (WHS Act). This act replaced the old OSH laws and introduced a more practical approach to safety, often supported by specialized WHS software, requiring businesses to manage risks upfront, rather than just reacting after something goes wrong.

The WHS Act in Western Australia Explained

If you've been operating in WA for a while, you'll remember the old Occupational Safety and Health Act 1984 (OSH Act), which many businesses supported with traditional OHS software. For decades, that was the rulebook for workplace safety. But the way we manage hazards has come a long way since the 80s.

To keep up, Western Australia brought in the Work Health and Safety Act 2020, which officially kicked off on 31 March 2022. This move aligned WA's laws with the national model WHS legislation used across most of Australia, creating a more consistent and up-to-date framework.

The big idea behind the WHS Act is simple: it shifts the focus from reacting to accidents to preventing them in the first place.

Think of it this way: the old approach was like parking an ambulance at the bottom of a cliff. The new WHS legislation is about building a strong fence at the top. The goal is to eliminate or reduce risks before they can cause harm.

Key Changes From OSH to WHS

The switch to the WHS Act was more than just a name change; it altered how safety is managed. For business owners and managers, this means getting your head around new terms and, more importantly, new responsibilities. A great first step is putting together a clear and complete WHS management plan to adapt to these new requirements.

Here are the most important changes you need to know:

- A Broader Definition of 'Worker': The Act’s protections now extend beyond direct employees. It covers contractors, subcontractors, apprentices, volunteers, and even labour-hire staff.

- The PCBU: The term 'employer' has been replaced by 'Person Conducting a Business or Undertaking' (PCBU). This expands responsibility to anyone who directs or influences work, whether it’s a large company, a sole trader, or a principal contractor.

- Positive Duty of Care: Company officers, like directors, now have a personal and proactive duty to ensure safety compliance. They can't just delegate and forget about it; they must actively make sure the business is meeting its obligations.

On a construction site, for example, this means the head builder (the PCBU) has to ensure the site is safe not just for their own employees, but also for the electricians hired as contractors and the apprentices there for work experience. Everyone on that site is covered under this single protective umbrella.

Who Is Responsible Under the WHS Act?

Under WA’s work health and safety laws, responsibility isn’t just for the person signing the paycheques. The legislation lays out a clear chain of responsibility, making safety a shared legal duty for everyone, from the boardroom right down to the factory floor.

Figuring out your specific role in that chain is the first real step toward getting compliance right.

The most significant change was the introduction of the Person Conducting a Business or Undertaking (PCBU). This term is intentionally broad, replacing the old, narrower concept of an 'employer'. A PCBU is any entity involved in work, whether it’s a sole trader, a partnership, a large company, or even a government agency.

This wider definition gets to the heart of how modern workplaces actually operate, often with multiple businesses working together on the same site. A single worker might be directed or influenced by several different PCBUs, and the law is clear: they all share a duty to keep that worker safe.

The Overlapping Duties of PCBUs

So, how does this work in the real world? Let’s take a look at a typical manufacturing plant. It’s easy to assume there’s just one PCBU involved, the company that owns the plant. But dig a little deeper, and it's rarely that simple.

Imagine the plant owner hires a specialist contractor to install a new piece of heavy machinery. At the same time, they bring in temporary staff from a labour hire firm to cope with a spike in production.

Suddenly, you have at least three PCBUs with overlapping safety responsibilities for the same workers, on the same site:

- The Plant Owner: They have the primary duty of care for the entire site. This includes making sure the building is safe, the existing machinery is maintained, and there are safe systems of work in place.

- The Installation Contractor: This PCBU is responsible for the safety of the installation process itself. They have to manage the specific risks their own equipment and work methods create.

- The Labour Hire Firm: They have a duty to ensure the workers they place are competent for the job and that the host workplace (the plant) is safe before sending them there.

If a labour hire worker gets injured while that new machine is being installed, all three PCBUs could find themselves on the hook legally. They have a shared, or concurrent, duty of care and are legally required to consult, cooperate, and coordinate with each other to manage safety risks.

Key Responsibilities under the WHS Act WA

To make this clearer, let's break down who is responsible for what under the WHS Act. The table below summarises the primary duties for the key roles defined in the legislation, using our manufacturing plant as a practical example.

| Role | Primary Duty | Practical Example (Manufacturing Plant) |

|---|---|---|

| PCBU | To ensure, so far as is reasonably practicable, the health and safety of workers and others affected by the work. | The plant owner ensures machinery has safety guards, provides PPE, and establishes clear traffic management rules. |

| Officer | To exercise due diligence to ensure the PCBU complies with its duties. | A company director regularly reviews incident reports and allocates budget for necessary safety upgrades. |

| Worker | To take reasonable care for their own safety and not adversely affect the safety of others. | An employee follows safety procedures, wears their required PPE, and reports a faulty machine to their supervisor. |

| Other Person | To take reasonable care for their own safety and follow reasonable safety instructions from the PCBU. | A visitor or delivery driver stays within marked walkways and follows all site safety signage. |

Understanding these distinct but overlapping duties is fundamental. Safety isn't just one person's job; it's a legal framework built on shared responsibility, where everyone has a specific part to play.

Officers: The People in Charge

Another crucial role defined in the legislation is the 'officer'. This isn't just a job title; it refers to a person who makes or participates in making significant decisions that affect the whole, or a substantial part, of the business. Think company directors, CEOs, and other senior executives.

Officers carry a specific, personal legal duty. They must exercise due diligence to make sure the business is meeting its WHS obligations. This means they can't just set a safety policy and walk away; they must actively verify that it’s actually being followed.

This duty of due diligence isn’t vague. It involves taking concrete, reasonable steps to:

- Keep their knowledge of work health and safety matters up-to-date.

- Properly understand the business's operations and the specific hazards and risks that come with them.

- Ensure the business has, and uses, appropriate resources and processes to manage those risks.

- Make sure there are systems in place for receiving and responding to safety information, incidents, and hazards in a timely manner.

Workers and Other Persons

The term 'worker' is also defined very broadly under the Act. It’s not just about direct employees. It includes contractors, subcontractors, labour hire employees, apprentices, trainees, and even volunteers.

Every worker has a legal duty to take reasonable care for their own health and safety. This boils down to a few key actions:

- Follow any reasonable safety instruction given by the PCBU.

- Cooperate with any reasonable safety policy or procedure.

- Make sure their actions (or inaction) don't put others at risk.

Finally, the Act also covers 'other persons' at a workplace. This is a catch-all for visitors, customers, and even passers-by. While they don't have the same duties as workers, the PCBU still has a responsibility to ensure their health and safety isn't jeopardised by the work being carried out. A simple example is a factory ensuring it has clear signage and safe, designated pathways for a visiting client.

Understanding Your Primary Duty of Care

At the heart of the WA WHS Act is the primary duty of care. This is the core legal responsibility a PCBU has to protect the health and safety of workers and anyone else who could be affected by what you do.

This duty hinges on a critical phrase: ensuring safety "so far as is reasonably practicable". This isn't an excuse. It’s a practical test that sets the standard for your legal obligations, meaning you have to do everything you reasonably can to manage health and safety risks.

Figuring out what's "reasonably practicable" isn't a gut feeling; it’s a specific process of weighing up several factors to make informed safety decisions.

What Reasonably Practicable Means for You

Deciding what's reasonably practicable involves a deliberate process of balancing the risks against the resources needed to control them.

You’re expected to take everything into account:

- The likelihood of the hazard causing harm: How likely is it that someone could actually get hurt?

- The degree of harm: If something goes wrong, how bad could it be? A cut finger or a life-changing injury?

- What you know about the hazard and its control: Is this a known problem in your industry? Are there standard, well-understood fixes?

- The availability and suitability of ways to eliminate or reduce the risk: Are there practical control measures you can implement right now?

- The cost of the control measure: Is the cost completely out of proportion to the risk?

Cost is only one piece of the puzzle, and it’s a weak argument on its own. You can only use cost as a reason for not acting if it's grossly out of proportion to the risk. For example, you can't skip fitting a $500 guard on a machine that could amputate a hand just to save a bit of cash. The risk far outweighs the cost.

Putting the Primary Duty into Action on a Construction Site

Let's get out of the theory and onto a real-world worksite. Imagine you're the PCBU for a new multi-storey building going up in Perth. Your primary duty of care isn't just a document you file away; it's a series of constant, practical actions that define your day-to-day operations.

Your primary duty of care is an active responsibility. It’s not about having a safety manual on the shelf; it's about the safety measures you have in action on the ground, every single day.

Here’s how a PCBU would apply these principles throughout a typical construction job:

1. Providing a Safe Work Environment

This is your foundation. Before a single tool is picked up, the site itself must be made as safe as possible.

- Initial Site Setup: You establish clear exclusion zones, put up secure fencing around the entire perimeter, and create designated walkways to keep people and vehicles safely apart.

- Managing High-Risk Work: The project involves working at heights, so you make sure appropriate scaffolding is erected by licenced pros and that guardrails are installed on every open edge. No excuses.

- Amenities: You provide essentials like clean drinking water, proper toilets, and a clean area for workers to have their break. This isn’t optional; it’s a fundamental WHS requirement.

2. Ensuring Safe Plant, Structures, and Systems of Work

Next up are the tools people use and the processes they follow to get the job done.

- Equipment Safety: All machinery, from the big excavators down to the hand-held power tools, is regularly inspected and maintained. If something is broken or faulty, it gets tagged out of service immediately.

- Safe Work Method Statements (SWMS): For any high-risk construction work like demolition or operating a crane, you ensure SWMS are developed with the people actually doing the work. These documents break down the steps, identify the risks, and detail the controls.

- Traffic Management: A clear traffic management plan is essential to coordinate the movement of delivery trucks, mobile plant, and workers. This includes simple but effective rules, like using a spotter for any reversing vehicles.

3. Providing Necessary Information, Training, and Supervision

You can have the best gear and procedures in the world, but they're useless if your team doesn't know how to use them safely.

- Site Induction: Every single person who sets foot on your site, from a first-year apprentice to a one-off delivery driver, gets a full site induction. This covers site-specific hazards, emergency plans, and the non-negotiable safety rules.

- Toolbox Talks: You hold daily or weekly toolbox talks to discuss the day's tasks, highlight any new hazards, and learn from any recent close calls. It’s a simple way to keep safety front and centre.

- Supervision: Foremen and supervisors are out on the floor, overseeing the work and making sure safe procedures are being followed. This is especially critical for new and young workers who need more guidance.

By taking these steps, you’re not just ticking boxes to comply with the law; you’re building a system where risks are actively found and managed. A key part of this is having a solid framework to evaluate hazards. You can get a better handle on this by exploring a detailed risk management matrix and learning how to apply it. This turns your legal duty into a practical, repeatable system for keeping your people safe.

How to Manage Risks and Consult with Workers

Knowing your duties under WA’s safety legislation is one thing, but putting it into practice is what really counts. True compliance boils down to two core processes that must work together: actively managing your risks and genuinely consulting with your workers.

These aren't optional extras; they're baked into the law. Think of risk management as the technical side of safety, the “what”, and consultation as the human side, the “how.” You simply can’t have effective safety without both.

The Four Steps of Risk Management

The WHS Act lays out a straightforward, four-step cycle for managing workplace risks. It’s a logical process designed to help you find and fix problems before anyone gets hurt.

Let's walk through it using a real-world example: operating a metal press in a factory.

1. Find the Hazards First up, you need to spot what could actually harm someone. On our factory floor, the hazards tied to that metal press could be its powerful moving parts, the deafening noise it makes, or the repetitive strain of manually handling heavy steel sheets.

2. Assess the Risks Once you’ve found a hazard, you need to figure out how serious it is. How likely is it to cause harm, and how severe could that harm be? The risk of a worker’s hand getting caught in the press might be a low probability, but the potential outcome is catastrophic. That makes it a critical risk you have to control.

3. Control the Risks This is where you take action. The legislation gives you a useful tool for this called the hierarchy of controls. It’s a ranked list of control measures, from most effective to least. Your job is to always aim as high up the list as you possibly can.

4. Review the Controls Safety isn’t a ‘set and forget’ exercise. You have to circle back and check that your controls are actually working. Is that new guard doing its job? Are people following the new safe work procedure? This final step makes sure your safety system keeps up with the reality of your workplace.

Using the Hierarchy of Controls

The hierarchy of controls isn't just theory; it’s a practical game plan for making your workplace safer. It gives you a clear order of operations.

Let’s apply it to our metal press:

- Elimination: Can you get rid of the hazard completely? This is the gold standard. Maybe a new production method means you don’t even need to press the metal anymore.

- Substitution: Can you swap the hazard for something safer? Perhaps you could invest in a newer, fully automated press that keeps hands well away from any danger zones.

- Isolation: Can you put a physical barrier between people and the hazard? This could be as simple as installing fixed guarding or fencing around the machine.

- Engineering Controls: Can you change the equipment itself to make it safer? A great example is fitting two-hand controls, which force the operator to have both hands on buttons far from the press’s moving parts.

- Administrative Controls: Can you change the way people work? This is where safe work procedures, specialised training, and clear warning signs come in.

- Personal Protective Equipment (PPE): This is your last line of defence, not your first choice. For the press operator, this would be things like safety glasses and hearing protection. PPE should only ever supplement higher-level controls.

The Legal Duty to Consult with Workers

Now for the part many businesses stumble on: you are legally required to consult with your workers at every single stage of this process. Consultation isn’t just a memo or a quick chat; it's a genuine, two-way conversation.

Consultation is a two-way street. Your crew on the floor has firsthand knowledge of the risks they face every day. Their input is valuable when it comes to creating safety solutions that are not just compliant, but practical.

This doesn't mean you need a committee for every decision. It means having solid systems in place so your team can have a real say in the safety matters that affect them.

Simple, practical ways to consult include:

- Toolbox Talks: Quick, focused chats before a shift to cover the day’s tasks and any immediate hazards.

- Safety Meetings: More structured catch-ups to discuss bigger WHS issues, review incident reports, and track progress.

- Direct Feedback: Just asking the person who uses the machine what they think when you're assessing a new piece of equipment or writing a new procedure.

Failing to get risk management and consultation right can have serious consequences. A robust system for both is your best protection. For a more structured way to handle all this, it’s worth learning how a modern safety management system can help turn these legal duties into a manageable, everyday process.

Enforcement Actions and Penalties to Know

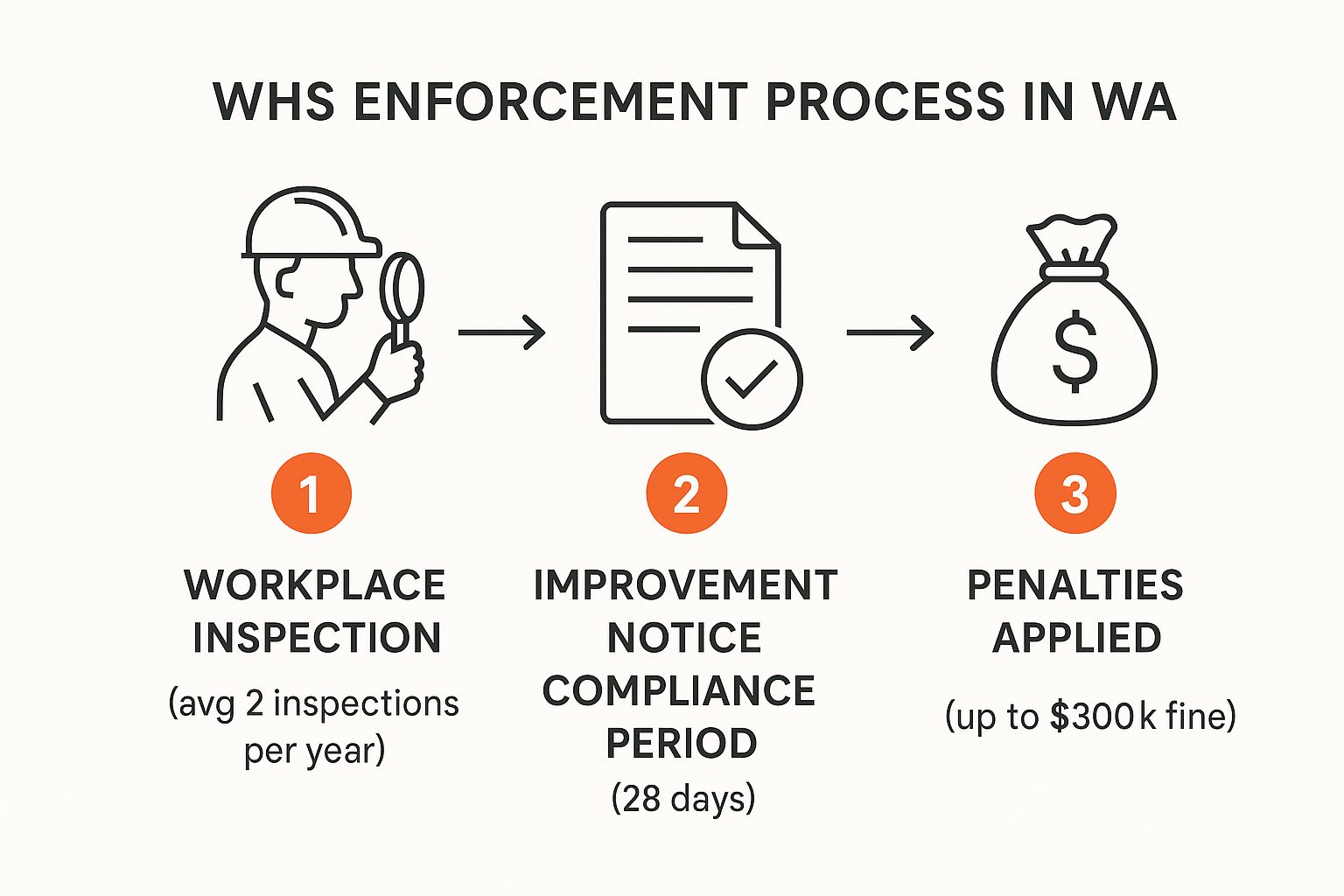

Knowing your duties is one thing, but understanding what happens when things go wrong is what really drives the message home. WorkSafe WA inspectors have serious powers to enforce the law, and the penalties for getting it wrong are not something any business can afford to ignore.

Think of an inspector like a referee on the field. Their job isn’t to hand out penalties for the sake of it; it’s to make sure everyone plays by the rules so no one gets hurt. If they see a problem, they have a few tools in their kit to stop unsafe work and get things back on track.

The Power of Inspector Notices

When a WorkSafe WA inspector turns up and spots a breach, they won't just have a quiet word. They have the power to issue legally binding notices that force you to take action. Ignoring these notices is a serious offence in its own right.

You'll most likely come across one of these three:

Improvement Notice: This is the most common one. An inspector issues it when they believe you're breaking a WHS rule. The notice will spell out exactly what the problem is and give you a firm deadline to fix it. A classic example is a missing machine guard. The notice will require you to install one by a specific date. Simple as that.

Prohibition Notice: This one is a much bigger deal. A prohibition notice means an inspector believes an activity poses an immediate or imminent risk to someone’s health or safety. It’s the equivalent of a red card. It stops the risky activity in its tracks, right there and then, until the problem is fixed to the inspector’s satisfaction.

Non-disturbance Notice: If a serious incident has already happened, an inspector can issue this notice to freeze the scene. It’s like taping off a crime scene. Nothing can be moved or interfered with, preserving everything so a proper investigation can uncover what went wrong.

The real point of these notices isn't to punish. It's to prevent an incident. They are legal tools designed to force a business to deal with a risk before it’s too late.

Major Penalties for WHS Breaches

If a breach of the WHS Act ends up in court, the consequences can be huge. The law outlines three categories of offences, and the penalties get steeper depending on how reckless or negligent the action was. It’s a tiered system designed to send a clear message: workplace safety is not optional.

Getting your head around these categories is vital. The potential fines and jail time really highlight why your duty of care has to be taken seriously. The work health and safety legislation WA was written with real teeth to hold both companies and individuals accountable.

Here’s a quick rundown of the offence categories and the maximum penalties that can be applied.

WHS Act Offence Categories and Penalties

| Category | Description | Maximum Penalty Example (Corporation) |

|---|---|---|

| Category 1 | This is the most serious. It involves reckless conduct that exposes someone to a risk of death or serious injury, without a reasonable excuse. | A fine of over $3.5 million. |

| Category 2 | A failure to comply with a health and safety duty that exposes someone to a risk of death or serious injury. | A fine of up to $1.8 million. |

| Category 3 | The least severe, but still a failure to comply with a health and safety duty that carries a hefty penalty. | A fine of up to $570,000. |

It’s crucial to remember these are maximums, and they don't just apply to the company. For a Category 1 offence, an individual PCBU or an officer of the company can face up to five years in prison. This focus on personal liability is a massive part of modern safety law, making it impossible for the people in charge to just look the other way.

The History of Safety Laws in WA

To really get a handle on today’s safety laws, it helps to know where they came from. For a long time, the main rulebook for workplace safety in Western Australia was the Occupational Safety and Health Act 1984 (OSH Act). This law was the standard for decades, but as workplaces evolved, the legislation had to keep up.

The old OSH Act wasn't set in stone. It went through some significant updates over the years, each one pushing towards stronger enforcement and making businesses more accountable. These changes weren’t just random tweaks; they were direct responses to workplace incidents and a growing understanding of what it actually takes to prevent them.

Key Changes Paving the Way for Modern Laws

A massive turning point came after a 2002 review by Robert Laing, which kicked off some major reforms. This update wasn't just about shuffling words around. It introduced much tougher measures and new ways to hold businesses responsible when things went wrong.

The history of work health and safety legislation in WA shows a deliberate shift. The law has moved from a basic set of rules to a framework demanding proactive risk management and personal responsibility from company leaders.

Some of the most critical reforms from that period included:

- Stronger Penalties: Fines got a lot bigger, and for the first time, gross negligence penalties could lead to imprisonment.

- New Accountability Tools: Safety and Health Representatives were given the power to issue Provisional Improvement Notices (PINs), a practical tool for getting safety issues fixed right there on the ground.

- Broader Coverage: The reforms finally acknowledged modern work arrangements, like labour hire, and brought government agencies fully under the microscope for prosecution. You can dig into these historical changes on WorkSafe's website.

These updates to the OSH Act really set the stage for the current WHS Act. They brought in the core ideas of officer liability and proactive safety duties that are now central to the work health and safety legislation WA we follow today.

Common Questions About WA WHS Legislation

When you're trying to get your head around the work health and safety rules in WA, a few questions always seem to pop up. Let's tackle some of the most common ones businesses ask.

Do I Have to Provide Water for My Workers?

Yes, absolutely. Under the WHS Act, a PCBU (that's you, the business owner or person in control) has a non-negotiable duty to provide workers with access to clean drinking water. This is a core part of your responsibility to provide a safe work environment and look after your team's welfare.

Think about it, especially working outdoors in the WA heat, this isn't just a nice-to-have, it's critical. While the law doesn't give you a magic number in litres per person like some other states do, the expectation is clear: you must provide enough for everyone, considering the temperature and how physically demanding the job is.

Providing readily accessible and cool drinking water isn't just good practice; it's a fundamental legal requirement. Failing to do so is a clear breach of your duty of care.

What’s the Difference Between a Hazard and a Risk?

This is one of the most important concepts to get right, and people mix them up all the time. It’s crucial not to use these terms interchangeably.

A hazard is anything with the potential to cause harm. A trailing power lead across a walkway is a classic hazard. So is a noisy machine, or working at height on a roof. It's the thing or situation.

A risk is the likelihood of that hazard actually hurting someone, combined with how bad the injury could be. For that power lead, the risk might be someone tripping and getting a minor bruise, or it could be them taking a serious fall and fracturing a hip.

Your job isn't just to spot hazards; it's to manage the risks that come with them. The work health and safety legislation WA is all about dealing with risks before they turn into incidents.

Are Volunteers Covered Under the WHS Act?

They sure are. The WHS Act defines a ‘worker’ very broadly, and this definitely includes volunteers. If your organisation relies on volunteers, you owe them the exact same health and safety duties as you do your paid employees.

Juggling all these duties and staying compliant can feel like a lot, but Safety Space is designed to make it simple. Our all-in-one platform helps you track hazards, manage consultations, and keep clear records, turning your legal obligations into a straightforward process. See how you can protect your team and your business by booking a free demo.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.